How to Prepare Bar Bending Schedule (BBS)

Preparing a bar bending schedule is an essential part of the construction process for any reinforced concrete structure. It involves detailing and listing all the steel bars, their sizes, shapes, and the number required for construction. A well-prepared bar bending schedule can help ensure that the reinforcement is placed correctly, the concrete structure is strong and durable, and the construction process is more efficient. In this blog post, we will discuss the steps involved in preparing a bar bending schedule and the importance of accuracy in this process. Whether you are a civil engineer, a construction professional, or a student, this guide will provide you with valuable information on how to prepare a reliable and accurate bar bending schedule.

A qualified engineer or technician who is responsible for the structural design of the project prepares a bar bending schedule (BBS). This document provides details about the reinforcement steel bars used in a reinforced concrete structure. It is an essential part of the construction process as it gives the necessary information for cutting, bending, and placing the steel bars accurately. The BBS ensures that the steel reinforcement in the concrete structure is in compliance with the design specifications, standards, and codes.

Steps to Prepare Bar Bending Schedule

1) Analyzing the Structural Design

To prepare a bar bending schedule, the engineer or technician responsible for the project must first analyze the structural design of the building. This involves identifying the various structural members, such as columns, beams, and slabs, and determining the required size and spacing of the reinforcement bars. Through this analysis, the engineer can create a plan for the required steel bars and ensure that the structure is reinforced in accordance with the design specifications.

2) Determining the Quantity of Steel Required

To proceed with the bar bending schedule, it is necessary to determine the quantity of steel required for each structural member based on the design specifications. This step involves calculating the weight of steel required per meter length of each bar and multiplying it by the length of the bar required for each member.

3) Arranging the Steel Bars

After determining the quantity of steel required for each member, the next step in preparing a bar bending schedule is to arrange the steel bars in the required shape and size. This step involves cutting and bending the bars according to the specifications provided in the structural design, which is essential for ensuring the structural integrity of the building. Skilled workers use various tools and machines to cut and bend the bars accurately, which is critical for ensuring that the reinforcement fits the structure and maintains its strength.

4) Assigning Bar Marks

Assigning a unique identification mark, called a bar mark, to each steel bar used in the structure is the next step. This helps in identifying the bar during construction and ensuring that it is placed correctly.

5) Creating the Bar Bending Schedule

To complete the process of preparing a bar bending schedule, the next step is to create a document that lists the details of each bar used in the structure, known as the bar bending schedule (BBS). The BBS includes essential information such as the bar mark, size, shape, length required, and the quantity required for each structural member. Additionally, the BBS also provides information on the placement of each bar and the location of lap joints to ensure that the steel is accurately placed during construction.

Advantages of Bar Bending Schedule

- Helps to Ensure Accuracy: By providing necessary information for cutting, bending, and placing the steel bars accurately, a bar bending schedule (BBS) helps to ensure the accuracy of the reinforcement steel bars used in a structure. This, in turn, improves the structural integrity of the building and ensures its safety.

- Reduces Material Waste: BBS plays an important role in reducing construction costs by accurately calculating the required quantity of steel for each member, thus reducing material waste.

- Improves Construction Efficiency: BBS helps improve construction efficiency and reduce construction time by providing detailed instructions for cutting, bending, and placing steel bars.

- Facilitates Quality Control: BBS records all the reinforcement steel bars used in a structure in detail, facilitating quality control and ensuring that the construction meets the required standards.

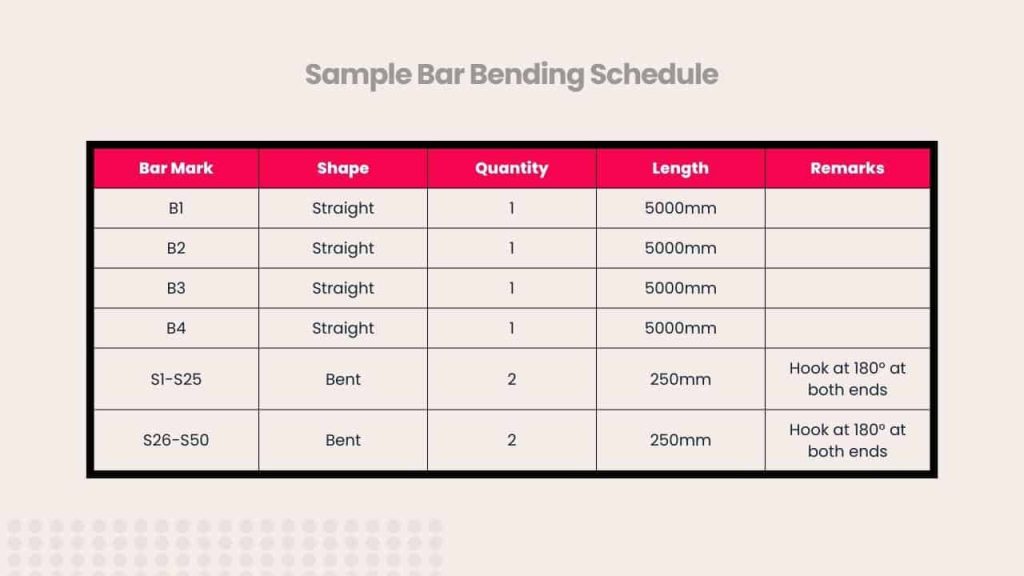

Sample Bar Bending Schedule

Here’s an example of a bar bending schedule for a simple beam:

Design specifications

- Beam dimensions: 150mm x 300mm x 5000mm

- Concrete grade: M20

- Clear cover: 25mm

- Reinforcement grade: Fe 415

- Spacing of main bars: 100mm c/c

- Spacing of stirrups: 200mm c/c

Calculation of quantity of steel required

- Area of steel required for main bars = (Area of section – Area of concrete)/% of steel

- Area of section = 0.15m x 0.3m = 0.045m^2

- Area of concrete = 0.03125m^2 (by deducting the area of steel from the total area)

- % of steel = 0.01 (1% of the area of the section as per design specifications)

- Therefore, area of steel required for main bars = (0.045 – 0.03125)/0.01 = 1.375m^2

Arrangement of steel bars

- Diameter of main bars: 12mm

- Number of main bars required: 4

- Total length of main bars required: 4 x 5m = 20m

- Diameter of stirrups: 6mm

- Spacing of stirrups: 200mm c/c

- Total length of stirrups required: (5000/200) x 2 = 50m (taking two legs of stirrups)

Bar Marking

- Main bars: 4 bars with marks B1 to B4

- Stirrups: 50 bars with marks S1 to S50

Bar Bending Schedule

This is a simplified example of a bar bending schedule for a beam. The actual BBS for a structure would have many more bars and would be much more complex.

Conclusion

In conclusion, the process of preparing a bar bending schedule is a critical step in ensuring the structural integrity and safety of a building. It involves accurately determining the quantity of steel required, arranging the steel bars in the required shape and size, creating the bar bending schedule document, and marking each bar with a unique identification mark. By following these steps, the construction process can be more efficient, cost-effective, and of higher quality. With a well-prepared bar bending schedule, the construction team can have a detailed record of the reinforcement steel bars used in the structure, which helps to facilitate quality control and ensure that the construction meets the required standards.

Try Onsite, #1 Tool For Site Tracking