A Smarter Way to Track Construction Materials, Including Steel, with Onsite

The materials used in a building project are very important, and how they are handled has a direct impact on both progress and profit. If you keep track of things on paper or in separate spreadsheets, you will nearly always run into delays and extra costs. Not having all the information, getting things late, or ordering too much can all slow down production and raise costs.

Why Steel Tracking is Critical for Construction Projects in India

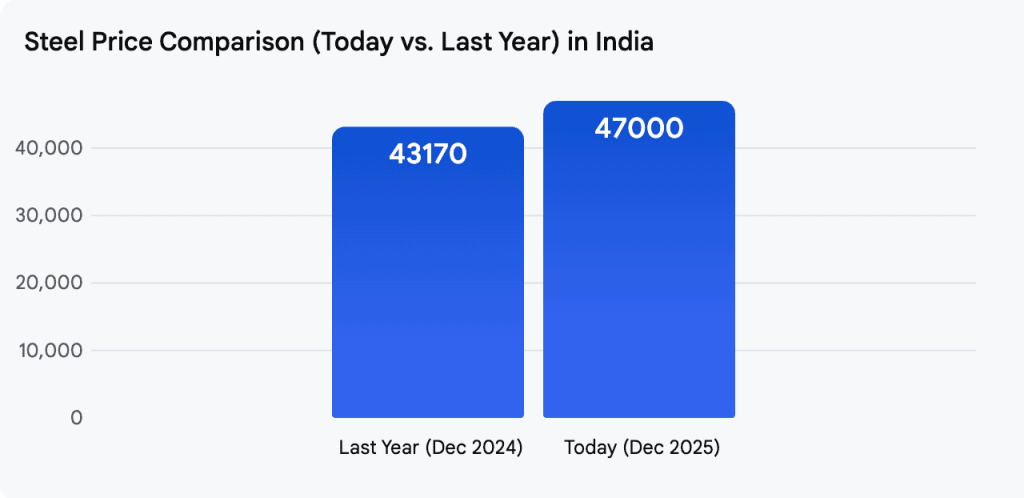

Steel prices in India keep changing. Sometimes prices go up suddenly, and contractors have no choice but to buy at a higher rate. When steel is not planned properly, this directly affects project cost and profit. Many contractors face problems like: Buying steel at the wrong time Ordering more steel than required Shortage of steel at site during critical work No clear record of how much steel is actually used Without proper tracking, steel cost goes out of control and margins reduce. This is why managing steel and other materials properly is very important for every construction project. As of December 2025, the price for Primary TMT steel is approximately ₹47,000 per metric ton (MT) which was approximately ₹43,170 per MT in December 2024.

Common Material Management Problems at Construction Sites

Most construction sites in India still manage materials using registers, WhatsApp messages, or Excel sheets. This creates many issues such as:

- No clear idea of how much material is available at site

- Extra steel or cement lying unused

- Material shortage during slab or casting work

- Wastage and theft going unnoticed

- No link between BOQ, purchase, and actual usage

- Site engineers and office team not on the same page

Because of these problems, projects get delayed and costs increase.

Onsite‘s Construction Material Management Software, which is made just for contractors and project managers, solves these problems. It lets teams see in real time how much materials they need, when they will be delivered, and how much stock they have, which speeds up the buying process and makes the project go more smoothly.

What is Construction Material Management?

Construction material management means: Planning material requirements as per BOQ Purchasing material at the right time and right quantity Tracking material received at site Issuing material properly to contractors and workers Monitoring daily material consumption Reducing wastage and unnecessary purchases A good material management system helps contractors save money and complete projects on time.

How Onsite Simplifies Material Management with Construction Material Management Software?

Centralized Material Tracking

When subcontractors at site use materials, they can just update the amount of material that has been used at the site. In this way you can know how much material has been used or how much is remaining at the site. This helps in streamlining your material inventory management.

Simplified Procurement

With the procurement feature you can generate orders, manage contracts, and budgeting. This feature involves finding suppliers, settling contracts, maintaining vendor relations, and making sure that products or services are delivered on schedule.

Live Cost and Stock Monitoring

With the help of Onsite, you can track how much material is being used at a site which helps in accurately monitoring stock availability and stock spent per day. At the same time, you can also check material requests or the material that has been ordered which keeps you updated on the cost being spent on the material.

Reducing Wastage and Losses

Construction Material Management Software brings coordination to the Inventory Management System. With transparency in material requests, material orders, and stock present at site, you can avoid ordering the same material twice. Everyone can get access to the same inventory data, removing confusion. Material approvals follow a structured workflow, which ensures accountability. This basically helps in fewer mistakes and accurate site requirements.

Access Instant Reports and Insights

With data available in your digital tool, you can immediately generate reports and get to know how much of each material has been used over a time period and which sites are consuming more (or less) than expected. You can also get to know if there is any over-ordering at a site.

Managing Steel Material Easily with Onsite Steel is one of the costliest materials in construction. Even small wastage leads to big losses. With Onsite, you can:

- Plan steel quantity as per BOQ

- Track steel purchases and deliveries

- Record steel issued to site and contractors

- Monitor daily steel consumption

- Compare planned vs actual steel usage

- Identify excess usage or wastage early

This helps contractors control steel cost and avoid unnecessary losses.

Conclusion

Construction projects rely on a steady supply of materials and accurate data. Without a proper system, tracking materials can quickly become chaotic and costly. Onsite’s Construction Material Management Software replaces scattered records with a single, real-time solution. It helps contractors reduce wastage, plan more effectively, and maintain financial discipline across all sites. By digitizing material control, Onsite ensures every project progresses with clarity, accountability, and cost efficiency.

FAQs

1. What is Construction Material Management Software?

It is a digital tool that helps contractors track material usage, manage procurement, monitor stock levels, and maintain accurate records for all construction sites.

2. How does Onsite simplify material tracking?

Onsite allows site teams to update material usage in real time, providing a centralized view of available stock and consumed quantities across all projects.

3. Can Onsite help reduce material wastage?

Yes. By providing transparency in orders, approvals, and stock availability, Onsite prevents duplicate ordering and ensures materials are used efficiently.