Construction Equipment Rental & Fleet Management Software in One Platform

From owned machines to hired assets, Onsite’s construction equipment tracking software gives you full visibility, accountability, and cost control.

Trusted by 10,000+ Construction Companies Worldwide

Ideal for construction teams running multiple projects with equipments

Built for construction teams managing equipment, tools, and machinery across multiple sites

01

Infra & Industrial Projects

Track heavy construction equipment and machinery across large project sites. Monitor equipment usage, maintenance schedules, and location to reduce downtime and improve asset utilization.

02

Building

Contractors

Manage site-to-site equipment movement, avoid idle assets, and maintain clear records of equipment allocation and usage across multiple construction projects.

03

Interior

Firms

Control tools and small equipment issued to teams, maintain accountability, and prevent frequent losses or unnecessary replacements during fast-moving interior projects.

How Onsite Asset & Equipment Management Software Works

Project managers hung on to old ways lose way more than the managers who have adopted modern ways. Construction management apps help project managers in so many ways. Our construction management app Onsite helps builders, contractors, and managers to efficiently manage project sites. Along with the whole construction project, you have the option of managing equipment efficiently. Get a demo today and manage equipment efficiently.

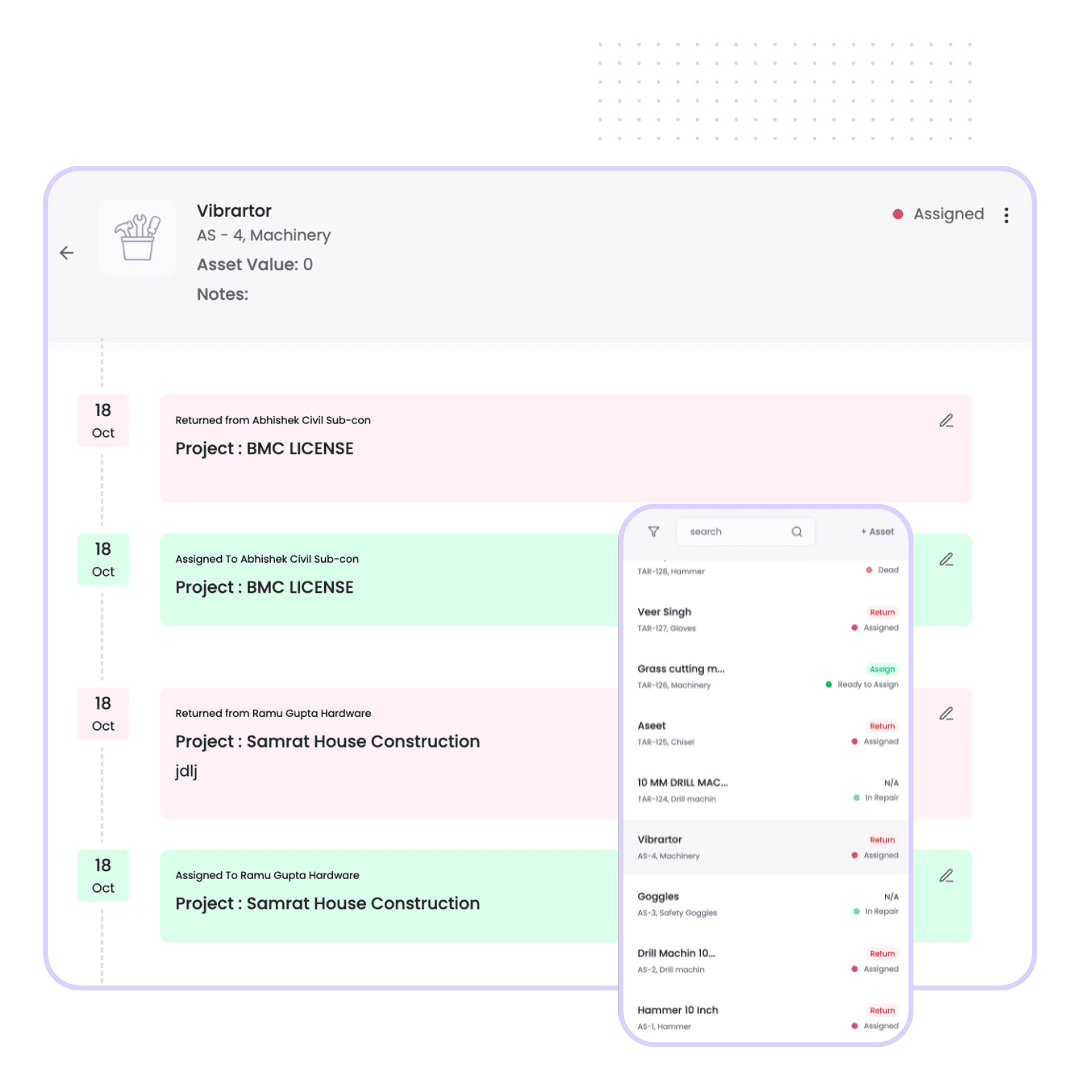

Centralized Equipment Assignment

Assign construction equipment and tools to projects, sites, or teams with full visibility. This ensures accountability and prevents equipment loss or misuse across locations.

Usage and Operating Hour Tracking

Track actual working hours and utilization levels to understand how effectively your construction equipment fleet is being used. Avoid idle assets and improve planning decisions.

Preventive Maintenance & Repair Records

Plan and record maintenance schedules using construction equipment maintenance software to reduce breakdowns, unexpected repairs, and downtime on site.

Location and Availability Visibility

Know where each piece of equipment is deployed in real time. This construction equipment tracking software helps teams locate assets quickly and avoid duplicate rentals or purchases.

Why Equipment Mismanagement Becomes a Cost Problem?

When you buy or rent equipment, the costs don’t stop there. Costs keep coming in the form of depreciation, maintenance, and downtime.

Traditional tools make it hard to spot issues before machines break down. A construction equipment maintenance software automates oversight and reduces downtime.

Equipment goes missing regularly

Tools and machinery move between sites on verbal requests with no documentation. You can't tell who took the excavator or which project is using the concrete mixer. Teams rent equipment you already own or buy duplicate tools. Site managers waste hours searching instead of supervising work.

No one owns equipment condition

Without operator accountability, people skip daily inspections and ignore maintenance needs. When a JCB breaks down or a generator disappears, you can't trace who last used it. Assets deteriorate faster because no one takes responsibility for upkeep.

Idle assets lose value daily

Equipment sits unused at finished sites while you rent the same machines elsewhere. Without utilization tracking, you can't redeploy idle assets to active projects. Capital stays locked in depreciating machinery generating zero returns.

Core Features of Onsite Equipment Management Software

Real-Time Machinery Tracking

Track where your equipment is across multiple projects. Be it any equipment crane or road roller, you can view their availability and usage from anywhere and at any time. You can even ask for immediate updates from the site manager through the app. Onsite acts as a full equipment fleet management software solution, letting you track assets across sites.

Utilization Reports

With Onsite, you can even see daily or monthly utilization data of the machinery. In these reports you can see how each machine is being used and at what site. You can also get how much fuel has been used. With built-in fleet tracking software and fleet tracking app support, supervisors always know field status.

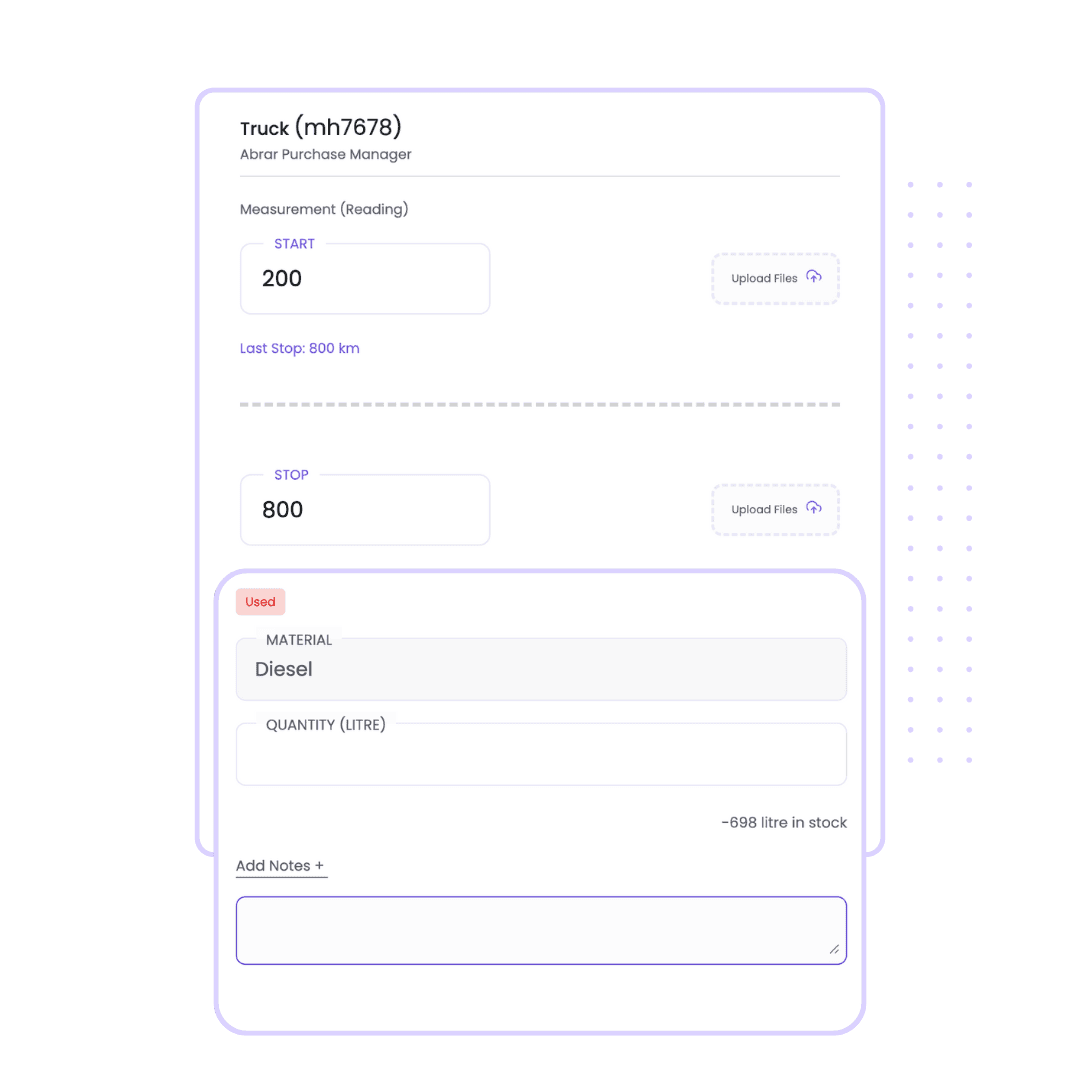

Fuel and Operation Logs

Keep record of how much diesel or petrol is being used every day and how many kilometers the machinery has been used. Maintain daily logs of fuel consumption, distance traveled, and hours operated for every piece of equipment. Onsite automatically flags unusual consumption patterns and allocates fuel costs to the correct project, helping you identify leakage and control one of construction's biggest hidden expenses.

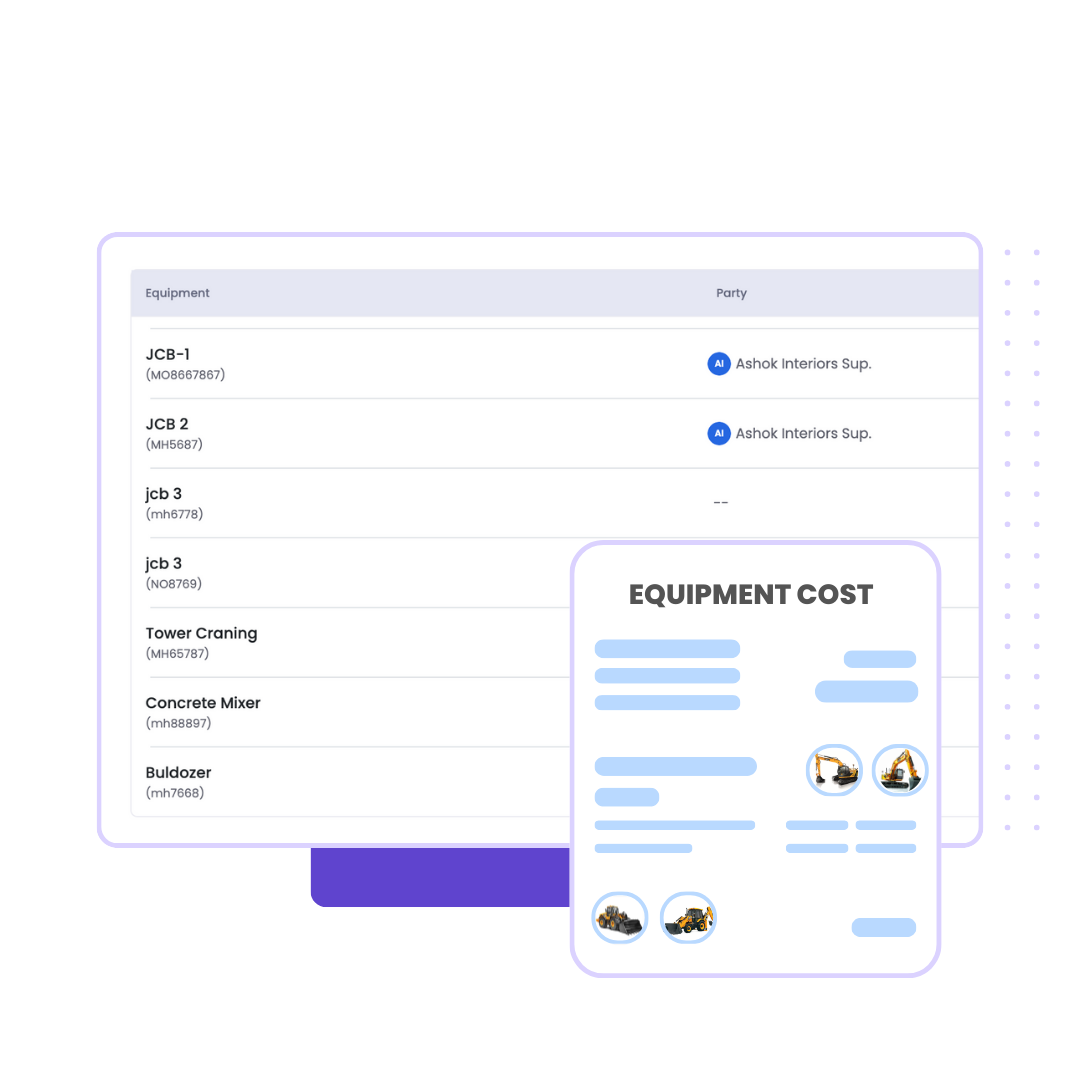

Add & Track Multiple Project Wise Equipments/Tools

You can add many equipment in the project and the data of all the equipment will be stored at one place. You can add equipment name, equipment number, whether it is rented or owned and if rented from what party. You can even upload images of the equipment while saving the details. This is how you can keep track and record of every equipment at one place.

Manage the Complete Equipment Lifecycle with Onsite

Track where your construction equipment is deployed, how it is being used, and when it needs maintenance. Onsite helps construction teams manage equipment allocation, usage tracking, and maintenance planning from a single system, reducing losses and improving utilization across projects.

Structured Equipment Requests and Allocation Control

Enable site teams to raise equipment reservation requests directly from the Onsite platform. Requests are mapped to project requirements and durations, allowing managers to approve and assign equipment with full visibility into availability and existing allocations. This ensures equipment is utilized efficiently and prevents conflicts or idle time caused by unplanned assignments.

Track Equipment Usage and Operating Hours Accurately

Maintain detailed usage records for every piece of equipment by tracking operating hours and usage entries at site level. These logs help teams understand actual utilization, identify underused assets, and plan maintenance activities based on real usage instead of assumptions.

Bring Control and Visibility to

Construction Equipment Management

Get free product demo of onsite construction equipment management software

See what our customers say about us

Manual Methods vs Structured Construction Equipment Tracking Software

Area

Software

Solutions

Visibility

Limited

Centralized

Usage Logs

Irregular

Consistent

Maintenance Planning

Reactive

Preventive

Location Tracking

Manual

Reliable

Accountability

Weak

Clear

Why Construction Equipment Management is Important?

Construction equipment management is filled with many factors that are needed to be considered like cost, use per day, fuel consumption, and usage. An unorganised construction equipment management can lead to many mishaps, but an organised equipment management helps you with a good life of equipment, saves you cost, avoids safety risks, and so on. Here are the benefits of structured construction equipment management

Improved Efficiency

To modernise the construction equipment management the project managers have adopted a modern way to handle equipment which is by using construction project management softwares like Onsite, Procore etc. So, by having an organised equipment management you can maximise the productivity of equipment. It also helps in avoiding overlaps and ensures when & where equipment is available.

Cost Saving

You can track your equipment and can get to know its fuel consumption. If it is consuming more than usual, then there must be some issue. Through deep monitoring you can fix the issue and save yourself from a long-term loss. Also, regular maintenance can identify and fix problems which also helps in expenses.

Safety Compliance

With the help of real-time updates, you can check how much work is being done every day by what equipment. By comparing the productivity, you can analyze which equipment is having problems. You can maintain your equipment accordingly. Well-maintained equipment reduces the risk of accidents and keeps you compliant with safety standards. Routine construction equipment maintenance and prompt heavy equipment repair keep machines operating longer and safer.

Rentals and Utilization

Construction companies often rely on equipment rental services for short-term needs. Whether it’s a boom lift, scissor lift, or heavy equipment rental, a strategy that ties rental periods to utilization helps reduce idle time and rental cost. Rental tools like excavators and cranes are essential additions during peak workload, but they must plug into your broader fleet strategy.

FAQs on Onsite Equipment Management Software

What is Onsite’s Equipment Management Software?

Onsite’s Equipment Management Software is a cloud-based solution designed to help construction companies track, allocate, maintain, and optimize equipment usage across multiple projects. It integrates GPS tracking, usage logs, preventive maintenance schedules, and cost reporting to ensure maximum ROI on assets.

What are the key features of Onsite’s Equipment Management module?

Core features include real-time equipment tracking, maintenance scheduling, automated usage logs, fuel consumption monitoring, operator assignment, downtime reporting, cost allocation to specific projects, and integration with Onsite’s project management and ERP tools.

Why should construction companies digitize their equipment management?

Digital equipment management eliminates manual errors, prevents asset loss, improves utilization rates, and reduces downtime through automated preventive maintenance. It also provides real-time data for better project planning and cost control.

How does Onsite track equipment usage on multiple projects?

Onsite uses GPS-enabled tracking and project-based allocation logs to record exact equipment locations, operating hours, idle time, and transfers between sites. Managers can view live dashboards for every asset, ensuring full visibility.

Can Onsite help reduce equipment downtime?

Yes. Onsite’s preventive maintenance alerts notify managers before breakdowns occur. Automated service reminders, maintenance history logs, and spare parts tracking ensure equipment is serviced on time, reducing costly downtime.

How does Onsite’s Equipment Management Software control equipment costs?

By tracking fuel consumption, repair expenses, rental fees, and operator hours, Onsite provides cost-per-hour and cost-per-project analytics. This enables managers to identify underperforming assets and make data-driven purchasing or disposal decisions.

Does the software support equipment rental management?

Yes. Onsite allows you to log rental contracts, track rented equipment usage, schedule returns, and record associated costs. It also provides reminders for contract expiry to avoid late return penalties.

Can I integrate Onsite’s Equipment Management with other systems?

Onsite supports integration with ERP, accounting, and payroll systems, enabling automatic cost allocation, billing, and financial reporting. It also works seamlessly with Onsite’s labour, material, and project management modules.

How does Onsite ensure data accuracy in equipment management?

All equipment data is recorded in real time via operator mobile apps, IoT sensors, and GPS tracking devices. This eliminates guesswork and manual errors, ensuring accurate usage logs, location data, and cost records.

Is Onsite suitable for large infrastructure projects?

Yes. Onsite’s scalable cloud platform can manage equipment fleets across multiple large-scale infrastructure projects, with unlimited asset tracking, role-based access controls, and centralized reporting for enterprise-level operations.