No More Missing Stock- Track Every Material Transfer in One Place

Knowingly or unknowingly, we often end up overordering material for our construction site. It is a common mistake which looks harmless but in reality it’s one of the most silent profit-eaters in any construction business. One of the biggest hurdles becomes when that over-ordered material is sitting in the warehouse and whenever you transfer it to a site, you seem to lose track of it. When you have multiple sites, changing site needs, and hundreds of items that are moving around, it is easy to lose track of material transfer, and it is easy for confusion to arise about where materials are and who is responsible for them. You do not have to go through this anymore because you can just use Onsite. Wanna know more? Keep reading.

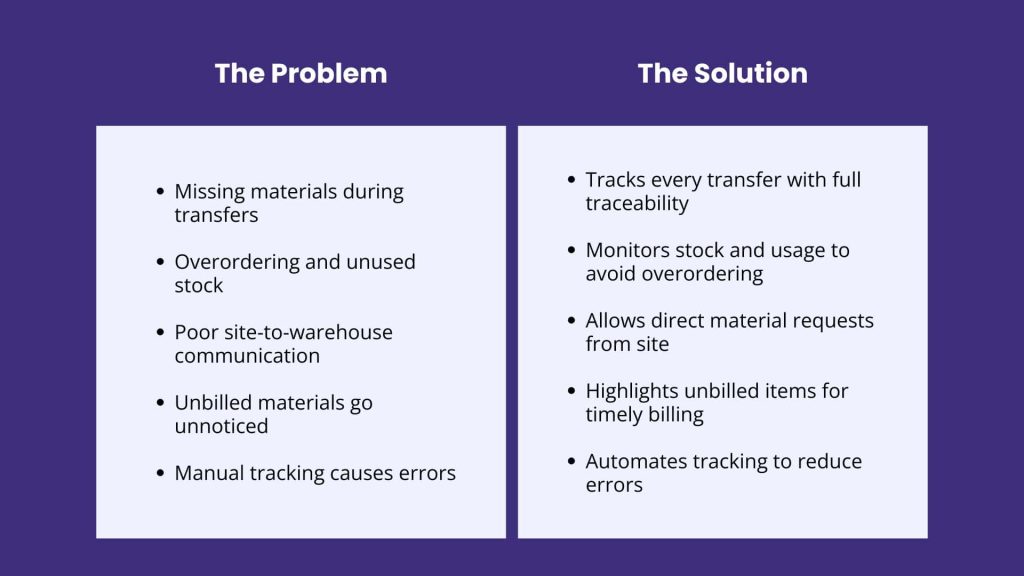

The Problem & The Solution of Material Transfer

How Onsite helps with Material Transfer?

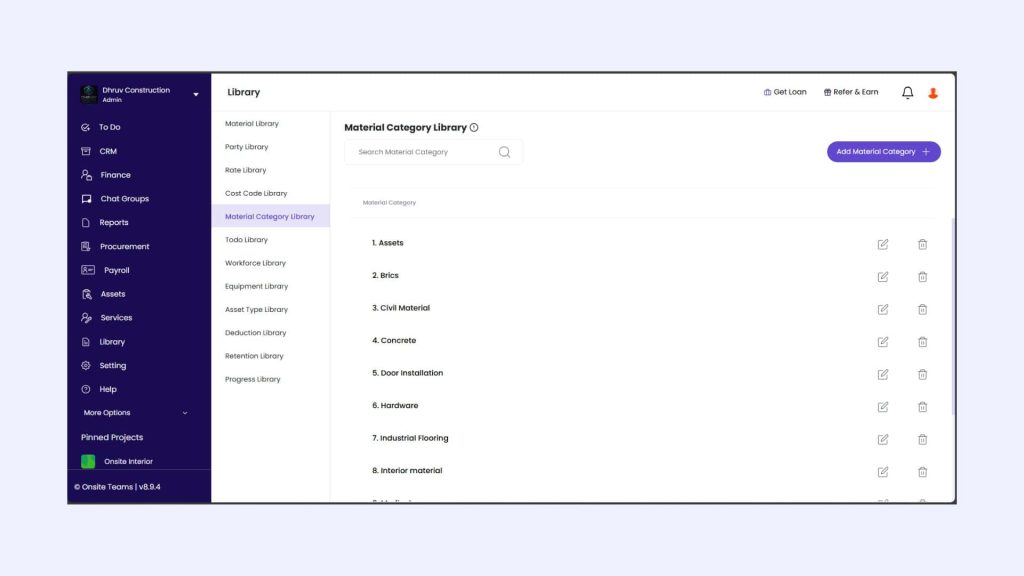

1. Stock Management

Onsite lets you manage your warehouse effortlessly. It organizes every stock record and its transactions. From here you can check your current stock, and you can also add a new stock whenever needed to. You can also download the report of your stocks and share it quickly. Every material transfer and received will be recorded here and will give you transparency. With the help of this you can achieve the goal of zero missing stock and gaining control over inventory.

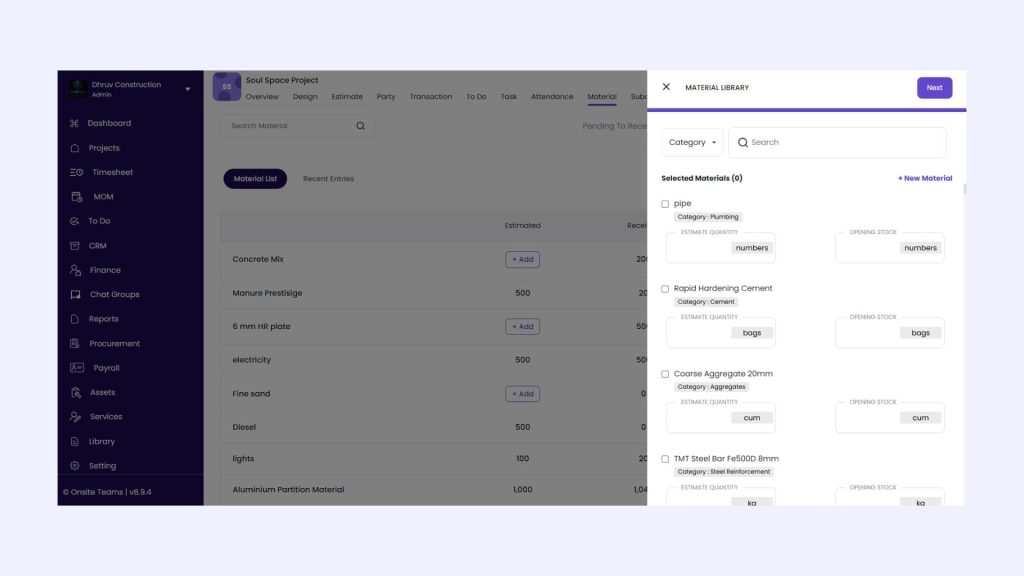

2. Material Request

Whenever your site team needs material at site, they can just make a request through our software. This will send material requests directly to the warehouse section. From where you can check all the material that has been requested and approve or reject the request accordingly.

3. Material Transfer

After receiving the request from the site, you can make a material transfer from Onsite’s warehouse section. With this feature, you can make a material transfer, and it can be recorded within the app. So that there will be no loss of material, better resource utilization, and complete traceability across all your sites. This ensures nothing goes to waste and every material movement is accounted for.

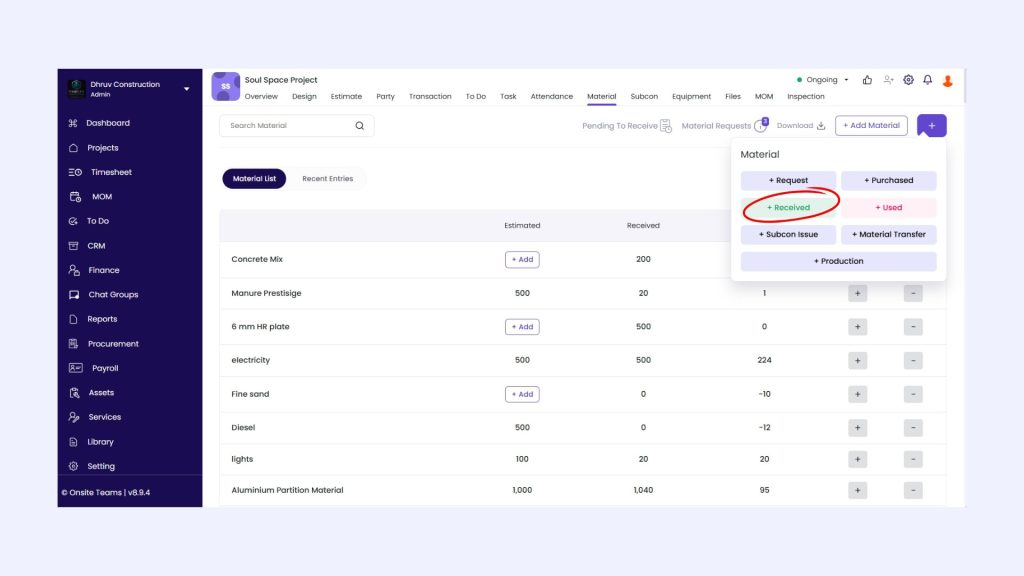

4. Material Received

There are times when the material was extra at a site or times when you order a new stock from a vendor, keeping its record is necessary. Once the purchase is made, it is also necessary to track if the material has been received at the site and if yes, how much of it was delivered. This also can be tracked within the app. Once the material is received, a transaction is being made. This keeps you updated about every movement of inventory and nothing goes unnoticed.

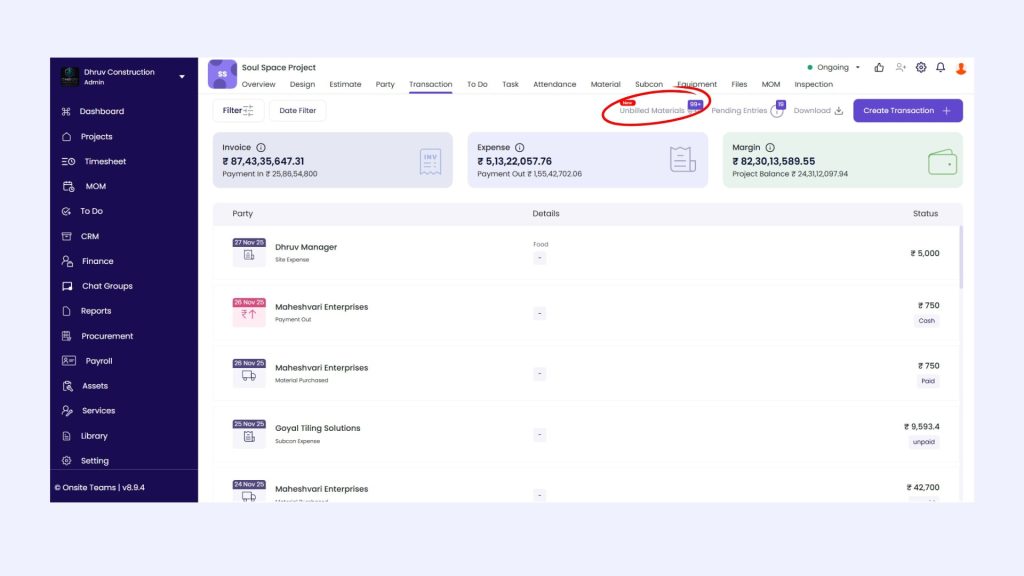

5. Transactions

Every transaction that has been happening in a company or a project can be tracked from this section. Whether you are transferring a material or making a purchase, every transaction can be logged here, and you won’t miss a single record. This is where you may view updates on the materials that have been purchased, returned, and other costs. Sales invoices and other bills, such as sub-con bills, can also be made. Thus, you can create bills and invoices here.

6. Unbilled Materials

There are often times when materials are available in your warehouse but haven’t been billed yet. To help with this, a dedicated button next to the transactions section lets you quickly view all unbilled materials. This feature keeps you informed and ensures nothing slips through the cracks. By staying updated on unbilled items, you can avoid revenue leaks, streamline your billing process, and maintain better control over your project finances.

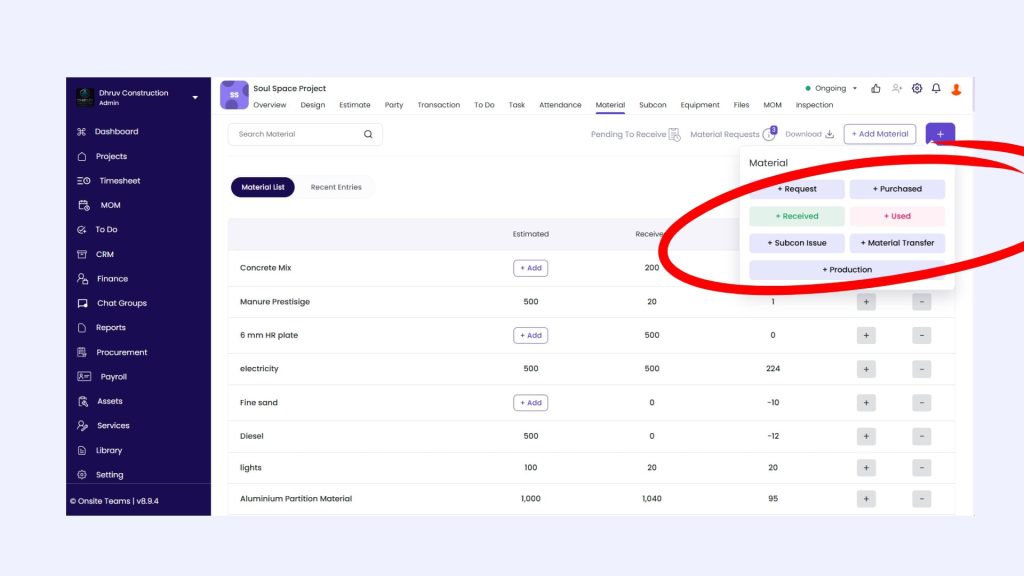

7. Material Process

In the material section everything is organized in a way that nothing will go unnoticed. The whole material process works like this in Onsite- You can make a material library on the company level and state their rates. So, whenever you want to make a BOQ, your rates will be automatically calculated based on the material library. And then a site manager or supervisor can simply make a material request. He can describe what material is needed and how much its quantity is needed. When a material is requested, it is up to the contractor or owner whether to approve this request or not. Once the material is approved, a purchase will be made by the backhand team. While making a material purchase, you can state if the full amount is being ordered or is it done partially. This purchase transaction will be recorded in the software, and you can even generate a report of it in a PDF form. From the procurement section, your backhand team can generate a purchase order. Once the purchase is made, it is also necessary to track if the material has been received at the site and if yes, how much of it was delivered. This also can be tracked within the app. Once the material is received, Transaction can be made The Site supervisor can also define how much of this material was used. You can even track the used material on an everyday basis.

With this whole process you can know what material money has been spent on. You can even track the usage of material every day at site, and you can know if there is material wastage or over ordering.

Ready for smoother material control?

Conclusion

Not just material transfer but you can get the whole warehouse management as well as a full multiple construction projects management. If you’re still tracking material movement via phone calls or spreadsheets, you’re leaving too much room for error. You need an organized system and Onsite is offering just that. Now make your material transfer and material processes easier and beneficial than ever. With a solution like Onsite, you bring everything under one roof, making stock tracking simpler, smarter, and far more reliable.

Also Read: Still Relying on WhatsApp for Construction DPR? Switch to Onsite

FAQs

1. What is site-to-site material transfer in construction?

Site-to-site material transfer refers to the movement of materials from one construction site to another. This is common when one site has surplus materials and another has a shortage. Tracking these movements is crucial to avoid loss and mismanagement.

2. How does Onsite help in tracking material transfers?

Onsite provides a centralized platform where every material request, transfer, and receipt is digitally recorded. This ensures complete traceability, eliminates manual errors, and gives real-time visibility into inventory movement across all your sites.

3. Can I generate reports of stock movement using Onsite?

Yes, Onsite allows you to download and share detailed reports of your stock transactions, including transfers, purchases, returns, and billing. This improves transparency and helps in financial planning.

4. How does Onsite prevent material wastage and overordering?

By tracking daily material usage and allowing site teams to request only what is needed, Onsite minimizes wastage. It also helps identify surplus stock, so it can be reused instead of ordering new materials unnecessarily.

5. What happens if a material is not billed in Onsite?

Onsite has a feature to track unbilled materials with just one click. This ensures no material is forgotten during billing, preventing revenue loss and ensuring better control over your finances.