Material Wastage in Construction: Causes and Control Methods

How untracked material decisions quietly reduce project profitability?

Most of the things in construction that can cause problems don’t show up immediately because the area of construction projects is vast and there are a thousand things happening all at once. One of these problems that stay hidden is material wastage. It eats up the profit silently every single day in operational decisions. Mostly, contractors end up ordering extra material like cement to avoid shortages. It raises the issues even before the site is ready to be executed. Ready mix concrete is ready, but because of the timing issue, it is being rejected. Finishing materials damaged while stored on site. Every single of these incidents seems like a minor one, but when they come together, they create a bigger financial loss.

On the top of project loss, globally, construction and demolition activities contribute roughly one-third of all solid waste generated. This study has indicated that around 15 to 18% of materials delivered at a construction site never turns into a complete project. This basically means that 15 to 18% of material at every construction site is getting wasted, which directly affects the profitability rather than appearing as an abstract efficiency concern.

What material wastage actually includes on construction sites?

Material waste doesn’t just happen when things break or are thrown away. It encompasses any situation when materials are bought, given away, or paid for yet don’t actually help with permitted work output.

Typical forms include:

- Overordering because of wrong estimations,

- Early issuance without execution readiness.

- Because of the absence of execution readiness, the concrete mix gets rejected.

- Leaks happen because of sequencing or coordination failures.

- The poor storage stand damaged the material.

- Leftover materials at project completion.

- Vendor invoicing exceeding recorded deliveries.

Whether dealing with concrete, aggregates, steel, timber, drywall, or finishing items, wastage represents cost without corresponding progress.

Why material losses often remain invisible until late stages?

When site activity is not interrupted, it is hard to catch the material-related losses early. Work on the site continues even if inefficiencies accumulate.

Common reasons include:

- ignorance,

- delayed measurement of consumption,

- lacking in progress tracking,

- manual record maintenance,

- poor visibility into site activities.

- Assumptions on quantities measured.

The industry research suggests the problems of material wastage arise from the root that is planning, and then continues to execution when planning and execution are disconnected. It is not from accidental damage. When the information reaches late and does not work against planning, the correction is no longer possible.

Primary contributors to material wastage in construction projects

Estimation buffers and imprecise quantity planning

Most of the time, material takeoffs have safety buffers and rounding to make sure there aren’t any shortages. In real life, these buffers typically mean that there is too much cement, aggregates, steel, and formwork that can’t be used again easily. What was designed to protect against risk ends up being extra that takes up cash and doesn’t add anything to the work that was done.

Unmonitored material issuance

When materials come from the store without any issuance to a specific task, it reduces accountability. The consumption of a material is not linked to the activity level progress. The loss here is happening on an everyday basis because there is no record or an organized way of consuming this material.

Rework resulting from execution mismatches

Changes in design, delayed approvals, and trade overlap forces rework and replacement. The rework consumes more material without giving any additional profit. It ends up becoming one of the biggest reasons for material wastage.

Storage-related losses

Often material resides before the site is ready. On top of this storage of material does not have a proper environment. It is not being stored at a warehouse. It is being stored in an open area. The weather exposure deteriorates the material, which also becomes a loss of material.

Reactive procurement under schedule pressure

To avoid any kind of disturbance in the execution process, teams overorder the material, the result of which becomes excess material on-site that is unused or becomes obsolete.

How material wastage evolves across project timelines?

There are different stages of Wastage behavior. It evolves as the project moves ahead.

- In early stages, wrong estimation and overordering takes place from incomplete information.

- During execution phases, reworks, which means double usage of material.

- Final stages come along with damages as well as leftover stock which goes to waste.

Each phase demands for attention and control measures rather than working on assumptions and generic supervision.

Financial and operational consequences of unmanaged wastage

Not keeping an eye on material waste leads to a lot of problems. Costs that are direct go up. Rework or last-minute rearranging can make schedules longer. When storage rooms get too full, it slows down mobility and lowers production. Instead of regular checks, billing and reconciliation evolve into arguments. Margins slowly get smaller, one project at a time.

Industry standards show that even small cuts in material waste can lead to big increases in profits. In many circumstances, the effect is bigger than the improvements that can be made by just optimizing labor, because material losses add up throughout the whole life of the project.

Metrics that bring material wastage into focus

| Metric | Insight |

|---|---|

| Planned vs issued quantity | Over-release detection |

| Material used vs work achieved | Efficiency gap |

| Rework-driven usage | Execution quality |

| Ageing inventory | Storage-related risk |

| Unbilled consumption | Financial exposure |

How Execution-Linked Material Controls Limit Wastage on Construction Projects?

Budget-Aligned Material Requests Reduce Excess Ordering

Material losses begin way before the site starts. The requests are raised to safeguard schedules, but not on confirmed requirements. These requests are reviewed without scope boundaries and more than necessary materials requests get approved. The result of which is that many unnecessary materials arrive at the site. Onsite is a construction management software that aligns material requests with project budgets. Each request is evaluated, worked closely on and being approved against quantity limits. This organized way of requesting or ordering material helps in preventing over ordering and unnecessary material accumulations.

Faster Approvals Minimize Emergency Procurement

When approval cycles are slow, it becomes a problem at a site. To avoid any kind of urgent orders, the teams end up ordering material in bulk, which leads to the decisions that often favor volumes over accuracy and increase material waste. Onsite health contractors work on approval workflows that mirror project authority lines. Each request comes with better visibility into quantities and the impact on finances. Last-minute purchases become more disciplined.

Structured Vendor Evaluation Prevents Defensive Purchasing

When it’s not known how much something will cost, how much of it will be needed, or when it will be delivered, procurement teams often order more to be safe. It minimizes the risk of running out of things, but it also raises the risk of having extra materials lying around on site.

Onsite helps close this gap by organizing how vendor quotes are compared and looked over. Prices, quantities, and delivery periods are all looked at at the same time in the same procurement flow. Contractors can place orders that are closer to what they really need instead of inflating the numbers to make up for uncertainty if they know exactly what vendors are promising. This keeps procurement under control and makes sure that materials flow in line with what the site really needs.

Inventory Visibility Reduces Loss from Duplication and Storage

Material wastage happens because there is no visibility on what is happening at the site. So many items remain unused while new materials are being ordered. Some materials have shortages, some are over-ordered, and some contain damage risk. Onsite records every single thing available at a construction site. With visibility into inventory, teams can know what is present at the site so that over-ordering or any shortage can be reduced.

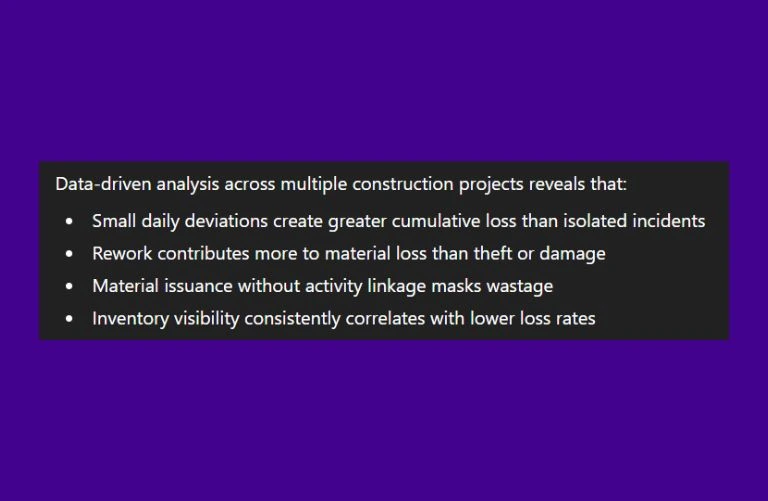

What AI-based analysis shows about material wastage patterns?

Conclusion

Construction activity doesn’t always lead to waste of materials. It comes from planning that isn’t complete, delayed visibility, and execution that isn’t connected.

When the transfer of materials stays in line with site readiness, verified usage, and financial checks, waste becomes something that can be managed instead of written off. Early visibility provides teams the time to change their plans. Late visibility merely proves the loss.

Real control starts when you measure material decisions as they happen, not after the damage is done.

Want to manage your material and avoid losses?

FAQs

Material wastage in construction refers to any construction material that is procured, delivered, or consumed but does not contribute to completed, approved work. This includes excess building materials, damaged construction supplies, rejected ready mix concrete, leftover aggregates, and materials lost due to rework or poor storage. Material wastage directly increases project cost without improving output.

The most common causes of construction material wastage include inaccurate material takeoff, buffer-driven procurement, unplanned material issuance, rework caused by execution errors, and lack of site inventory visibility. Materials such as concrete ready mix, aggregates, drywall, timber, and finishing materials are especially vulnerable when planning and execution are misaligned.

Ready mix concrete wastage often occurs due to poor coordination between batching, delivery, and placement. Delays on site, incorrect quantity estimation, or changes in work readiness can lead to rejected or unused concrete. Without execution-linked ordering, ready mix concrete losses become difficult to recover.

When teams do not know what construction materials are already available on site, they raise new requests unnecessarily. This results in duplicate procurement, excess stock, and damage due to prolonged storage. Real-time visibility into building supplies and site inventory helps contractors reduce repeat ordering and hidden wastage.

Yes. Material wastage directly reduces contractor margins because it represents cost without billable output. Studies show that even a small reduction in construction material wastage can result in noticeable profit improvement, often more than gains achieved through labor optimization alone.

Key metrics include planned versus issued quantities, material consumption compared to work completed, ageing of site inventory, and unbilled material value. Tracking these indicators helps contractors identify wastage related to construction materials, aggregates, and ready-mix concrete before losses escalate.

Manual tracking methods rely on delayed updates and retrospective reconciliation. Construction execution changes daily, but spreadsheets and paper registers capture information after the fact. This lag prevents timely control of material usage and allows wastage of building materials and construction supplies to go unnoticed.

Execution-linked systems connect material requests, approvals, procurement, delivery, inventory, and billing within a single workflow. This ensures materials are ordered based on verified need, issued against execution readiness, and paid for only when delivered. Such systems help reduce wastage of construction materials, ready mix concrete, and aggregates by improving visibility and accountability.

While reducing wastage supports sustainable construction materials and lower environmental impact, the primary driver for contractors is financial control. Less wastage means lower material cost, fewer delays, and improved predictability in execution and billing. Sustainability benefits become an outcome of better operational discipline.