Stop Wasting Materials,

Start Maximizing Profits

Handle everything from estimation to delivery to payment without manual headaches with Onsite construction inventory management software.

Trusted by the 10,000+ Construction Companies

Onsite is trusted by top builders and contractors for smart material management, accurate cost tracking, and faster project delivery. Onsite is the most easiest & user friendly inventory management software for construction industry

Ideal for Construction Teams Managing Materials, Inventory & Costs

A practical inventory management software for construction industry teams that need real-time visibility, approval control, and cost discipline across sites.

01

Developers &

Contractors

Track materials across multiple sites using a centralized inventory software for construction company, ensuring budget adherence and minimal wastage.

02

Infra &

EPC Firms

Manage high-value bulk purchases, centralized procurement, and site-wise inventory using a scalable construction inventory management system.

03

Industrial & Fabrication Projects

Monitor inventory levels, consumption, and stock movement across plants and yards with accurate construction inventory software.

04

Interior

Firms

Control fast-moving materials, frequent deliveries, and vendor coordination using lightweight yet powerful inventory management software for construction industry.

How Onsite Material

Management Software Works

Onsite connects material planning, procurement, inventory, and billing into a single construction inventory management system, giving teams end-to-end visibility from request to site usage.

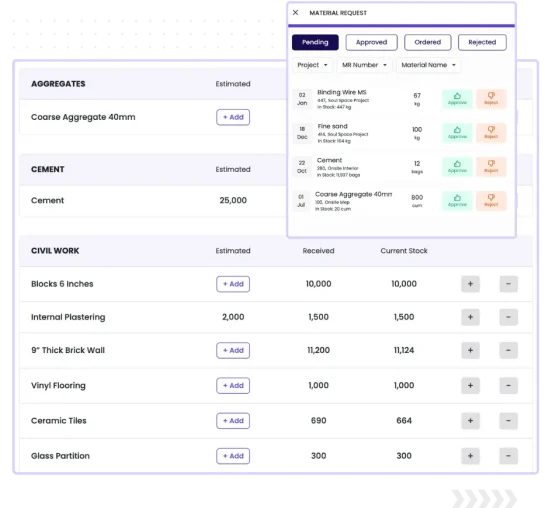

Budget-Linked Material Requests

Site teams raise material requests directly mapped to project budgets, ensuring every requirement is planned and justified before procurement.

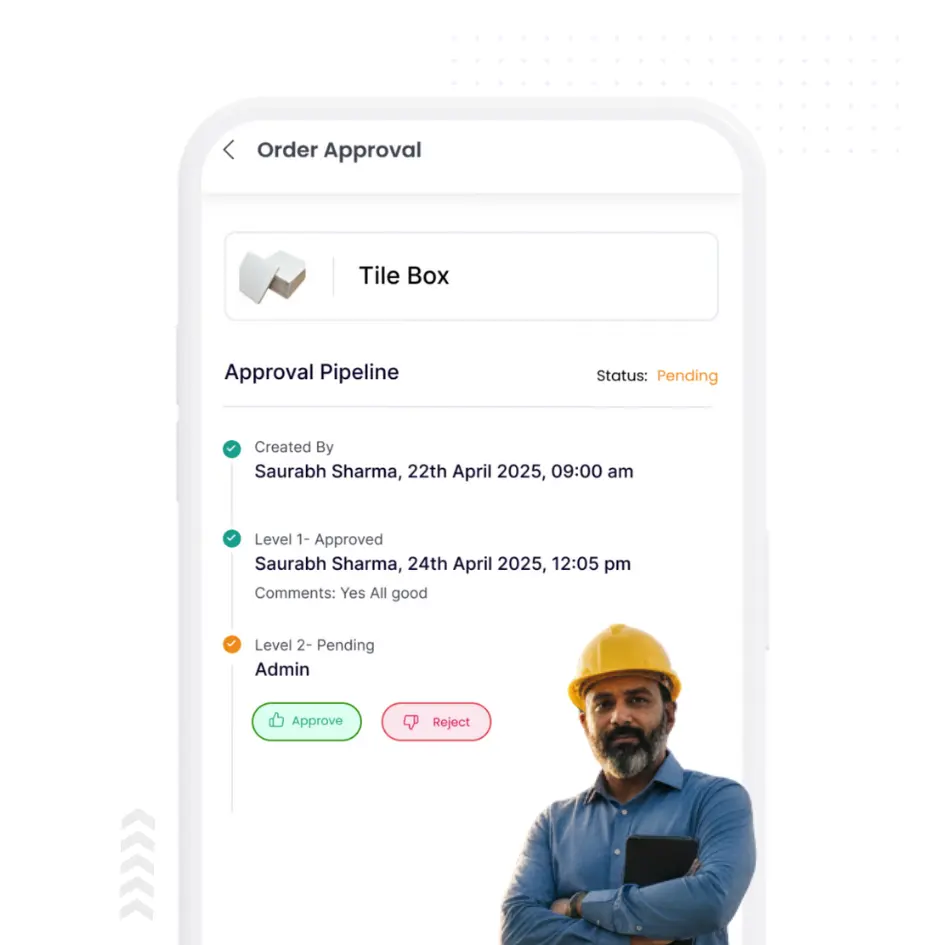

Approval-Driven Procurement Workflow

Configurable approval hierarchies help speed up decisions while maintaining financial discipline, this eliminates informal or duplicate material orders.

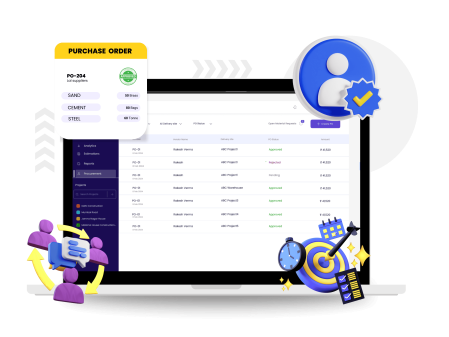

Purchase Orders, Delivery & Inventory Tracking

Generate digital POs, track delivered quantities, and maintain real-time site inventory. Onsite acts as a live construction inventory tracking system, ensuring stock levels and usage are always visible.

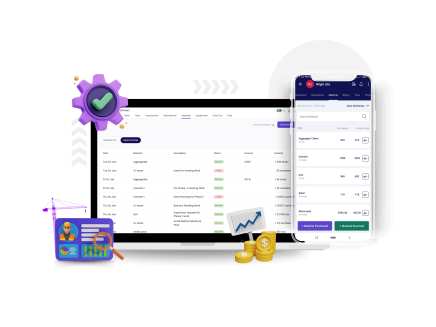

Bill Validation Against Actual Receipts

Vendor bills are validated against received quantities and recorded deliveries—preventing overbilling and mismatches.

Why Material Tracking Must Be Digital

Why Material Tracking Must

Be Digital

Materials form the backbone of every construction project, yet they are also the least controlled cost head when managed manually.

When companies rely on paper-based logs or spreadsheets nstead of a material management software for construction,, they face the following issues.

Managing materials is one of the most challenging aspects of any construction project. When companies rely on paper-based logs or spreadsheets, they face the following issues.

Inaccurate Stock Records

Without a construction material management software, manual entries often lead to errors in tracking cement, steel, & other construction materials. This results in mismatched inventory data for cement, steel, aggregates, and other high-value materials, making stock levels unreliable across sites.

Delayed Procurement

In the absence of a structured inventory management system for construction company workflows, material requests move informally between site and office. Approval delays stall procurement, causing idle labour, disrupted schedules, and last-minute emergency purchases at higher rates.

Material

Wastage & Theft

Without a material tracking system, pilferage and misuse often go unnoticed. This causes unnecessary expenses and project delays. Without a proper construction inventory tracking mechanism, wastage silently increases project costs and directly impacts profitability.

Poor Communication

Without a connected construction inventory management software, procurement teams, site engineers, and accounts work on disconnected data. Lack of a connected platform means delays in construction projects.

Core Features of Onsite Construction Inventory Software

With Onsite Construction Management Software, material tracking becomes effortless—whether you are at the site or in the office. The software connects your material planning, inventory tracking, billing, and accounting processes in one platform.

Raise Budget-Linked Material Requests with Full Control

Create structured material requests mapped to project budgets and site needs. Site teams raise material indents digitally with required quantities, specifications, and delivery timelines — ensuring every request follows a controlled, approval-driven process.

Approve, Order & Track Materials Without Delays

Speed up approvals and convert requests into purchase orders seamlessly. Configurable approval hierarchies ensure faster decisions without compromising cost control. Approved requests move directly into PO creation for error-free procurement.

Track Deliveries, Inventory & Usage in Real Time

Ensure every delivered material is received, recorded, and consumed correctly. Onsite tracks deliveries against POs, updates site inventory instantly, and records material usage — giving you real-time visibility into stock movement and preventing leakage.

Gain Full Control Over Construction Materials and Inventory

Book a free demo of Onsite material management software and track materials from request to usage while eliminating wastage and billing mismatches.

Why Construction Companies Choose Onsite Material Management Software

Stop Hidden Material

Leakages

Most construction losses happen silently — through over-ordering, untracked stock, or mismatched bills. Onsite’s construction inventory tracking system ensures every request, delivery, and usage is recorded and auditable.

Centralize and Control Material Requests & Approvals

Unorganized material requests lead to delays and budget overruns. Onsite introduces approval-based workflows within a material management software for construction, ensuring every request follows budget and authority rules.

Ensure Vendor Billing Accuracy

Vendor bills are often approved without matching them against actual deliveries. With Onsite’s construction inventory management software, bills are validated against received quantities — preventing overbilling and disputes.

Get Real-Time Inventory Visibility Across Sites

Without a centralized system, site inventory remains invisible to management. Onsite acts as a unified construction inventory management system, giving real-time visibility into stock levels, consumption, and pending requirements.

Streamline your procurement process & enhance efficiency.

Maintain control over project budgets, get smoother operations, and improve project outcomes.

Get better control over material inventory.

Improve cost tracking, manage expenses, minimize waste, and improve profitability.

20+ Reports

Manage Financial processes, improve decision-making, and enhance overall project outcomes of different parties.

Efficient communication & coordination

Communicate material needs and facilitate timely material acquisition. It helps with meeting project deadlines and minimize delays.

Track overall activity of warehouse

Streamline material management processes, reduce operational costs, and ensure project success.

Learn More About Construction Inventory Tracking

Read our articles and learn how Onsite construction inventory software can help you streamline your material management process

FAQs on Onsite Inventory Management Software for Construction Industry

What is construction material management software?

Construction material management software is a digital tool that helps contractors and builders plan, track, and control materials across multiple sites. Onsite’s material management platform simplifies everything from material requisition and inventory tracking to vendor billing and financial integration, reducing wastage and delays.

How does Onsite material management ERP software work?

Onsite ERP software offers a complete material management system with mobile and web connectivity. Site teams raise material requests through the app, managers approve in real time, and stock levels update automatically across all locations. It tracks material movements, generates digital Goods Receipt Notes (GRNs), and integrates with accounting software like Tally and Zoho Books for accurate billing.

Why do construction companies need digital material tracking?

Manual tracking leads to stock shortages, wastage, and uncontrolled costs. A construction material tracking software like Onsite gives real-time visibility into stock levels, consumption, and vendor deliveries, ensuring efficient procurement, budget control, and reduced material loss.

Does Onsite material management software provide BOQ-based material management?

Yes. Onsite links material requests and usage directly to the project BOQ, enabling accurate planning and real-time budget versus actual tracking. This ensures procurement aligns with approved quantities and project cost estimates.

Can Onsite ERP integrate with accounting software for material billing?

Absolutely. Onsite syncs with Tally and Zoho Books, making it easy to reconcile vendor bills and project expenses. This eliminates manual errors and accelerates financial approvals, making it a leading choice for material purchasing software.

How does Onsite construction management software ensure data security for material management?

Onsite uses AWS cloud hosting with data encryption and daily backups to protect sensitive information. It also provides role-based access control, so only authorized users can view or edit financial and inventory data.

Can I track materials across multiple construction sites with Onsite ERP?

Yes. Onsite’s construction material management software provides a consolidated dashboard for inventory across multiple projects. This ensures centralized control for business owners and efficient redistribution of materials.

Does Onsite ERP help in preventing material wastage and theft?

Yes. With real-time material tracking for construction and DPR-linked consumption records, Onsite improves transparency and accountability. This reduces material wastage and pilferage, helping companies save up to 7% on costs.

How quickly can Onsite material management software be implemented?

Unlike traditional ERPs that take months, Onsite can be implemented in just 1–2 weeks. The platform provides mobile and web access, making it easy for teams to adopt without lengthy training.