Track Inspections, Manage Checklists & Ensure Task Quality On-Site

The easiest way for builders, contractors, and developers to manage checklists, track inspection status, and resolve issues faster.

Teams That Benefit Most from Construction Quality Software

Best suited for projects requiring consistent inspections, documentation, and issue traceability.

01

Developers &

PMC Teams

Developers and PMC teams use Onsite’s construction quality management software to standardize inspection processes, maintain consistent quality records, and ensure compliance across multiple sites.

02

Contractors & Interior Firms

Contractors and interior firms rely on construction quality control software to record inspections, log observations, track defects, and close quality issues without relying on paper checklists or WhatsApp photos.

03

Infra &

Industrial Firms

Infra and industrial teams use quality management software for construction to manage inspections across disciplines, maintain traceability, and track compliance status throughout project execution.

Trusted by 10,000+ Construction Companies Worldwide

Why Construction Companies Need Quality Management Software

Missed Inspections Cause Costly Rework

Manual or inconsistent checks lead to defects that are discovered late, resulting in demolition, delays, and increased material/labour cost.

No Standardized Checklists Across Sites

Teams rely on memory or old PDFs, causing uneven quality and avoidable mistakes across multiple locations.

Issues Don’t Reach Management on Time

When inspections happen over WhatsApp or calls, deviations get lost, delaying corrective action.

Why Choose Onsite Quality Management Software

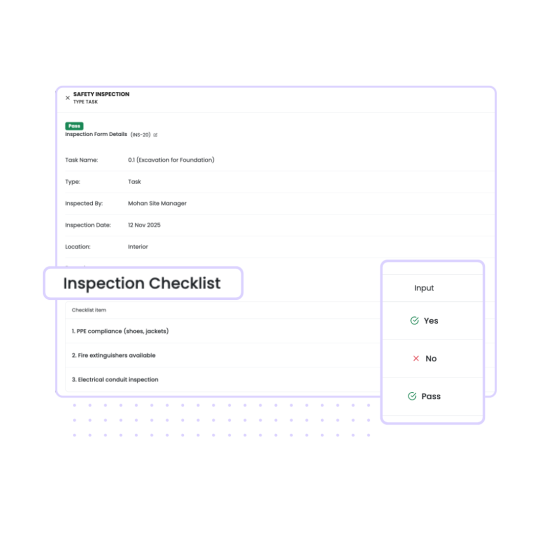

Standardize Quality Checks With Digital Checklists

Create discipline-wise checklists for civil, electrical, interior, and structural tasks. Onsite ensures your team follows the same quality protocol across all projects.

Capture Inspections With Photos, Remarks

Every inspection becomes evidence-backed. Site engineers can attach photos, add remarks, mark exact deviations, and assign the issue to the responsible person.

Close Issues Faster With Real-Time Coordination

When a deviation occurs, Onsite alerts supervisors and management instantly. Escalations ensure no pending issue gets ignored.

Why Choose Onsite Construction Quality Management Software

Reduce Rework with Structured On-Site Quality Control

Onsite is a construction quality management software designed for real on-site use. Site teams can perform inspections directly from the field using structured checklists, ensuring quality control happens during execution— not after problems surface.

Standardized Inspections Across Projects and Teams

With digital checklists and defined inspection formats, Onsite ensures the same quality standards are followed across all projects. This helps construction companies maintain consistent on site construction quality control, even when multiple teams or contractors are involved.

Clear Visibility into Quality Issues and Non-Compliance

Onsite allows teams to log non-compliance during inspections, assign responsibility, and track corrective actions. This transforms quality management from informal follow-ups into a structured construction quality control software workflow with accountability.

Complete Inspection History and Quality Traceability

Every inspection, observation, photo, action, and approval is recorded in one system. This onsite software inspection and compliance capability provides a reliable audit trail for internal reviews, client discussions, and continuous quality improvement.

FAQs on Onsite Construction Quality Management Software

What is Onsite’s Construction Quality Management Software?

Onsite’s Quality Management Software is a digital system that helps construction companies manage inspections, track quality checklists, capture issues with photos, and maintain complete traceability from site to office.

Why do construction companies need quality management software?

Because manual inspections lead to missed checks, inconsistent quality, and costly rework. A digital system ensures standardization, accountability, and real-time visibility across all teams.

What features does Onsite offer for quality management?

Onsite includes digital checklists, photo-based inspections, instant deviation alerts, audit trails, and analytics to track recurring quality issues and improve project standards.

How does Onsite reduce rework in construction projects?

By ensuring teams always follow standardized checklists, raising deviations immediately, and tracking corrections through a transparent audit trail — preventing mistakes from repeating.

Can multiple teams collaborate on inspections inside Onsite?

Yes. Engineers, supervisors, PMC teams, developers, and consultants can collaborate in real time. Everyone sees inspection status, pending issues, and corrective actions instantly.

Does Onsite allow photo and remark-based inspections?

Absolutely. Every inspection entry can include photos, notes, location, timestamp, and the responsible person — ensuring clear proof and faster resolution.

How does Onsite Quality Management Software improve accountability on site?

Every inspection has a traceable record of who checked it, what issue was raised, and who resolved it. This audit trail improves responsibility and transparency.

Is Onsite useful for multi-site developers and contracting firms?

Yes. Onsite is designed for developers, contractors, EPC firms, and PMC teams managing multiple projects simultaneously where quality consistency is critical.

Can Onsite track recurring quality issues?

Yes. Onsite’s quality analytics highlight repeated defects, problem areas, and contractor-wise performance metrics — helping companies improve long-term standards.