Construction Production Management Software — Built for Real Project Execution

Create Material Mixes, Manage Fabrication & Control Site Production. For contractors managing in-house fabrication or material batching, production control directly affects project timelines and cost.

Who Should Use Construction Production Management Software

01

Infra &

EPC Companies

Manage high-volume concrete, plaster, or asphalt production by standardizing material mixes, recording batch-wise inputs and outputs, and tracking actual consumption against planned quantities.

02

Industrial

Firms

Track in-house production used for industrial construction projects by monitoring material usage per batch, maintaining consistent quality, and linking production data with inventory and cost control.

03

Building

Contractors

Run on-site material batching and mixing operations with approved mixes, daily batch records, and real-time visibility into raw material consumption to prevent wastage and rework.

Trusted by 10,000+ Construction Companies Worldwide

Why Construction Companies Need Production Management Software

Inconsistent Material Mixes Affect Quality

Without a standard mix recipe, material proportions vary from batch to batch — leading to weak concrete, poor plaster finish, or rework.

Manual Recording Causes Hidden Material Loss

Paper logs cannot accurately track how much raw material is consumed vs how much output is produced.

No Integration with Material Inventory

Most teams don't know which material was used where, making stock planning inaccurate and increasing procurement cost.

Production Cost Isn’t Linked to Project Budgets

Companies often discover overruns only after work is completed, affecting project profitability.

Why Choose Onsite Production Management Software

Standardize Material Mixes for Consistent Quality

Define and manage production mixes — like M10/M20 concrete, mortar ratios, plaster mixes, fabrication specs — and ensure every batch follows the approved composition.

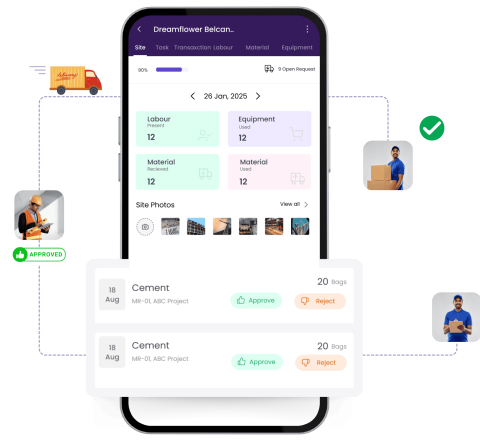

Track Input vs Output With Complete Transparency

Record raw material consumption and production output for each batch or shift. Onsite highlights deviations so you can control waste early.

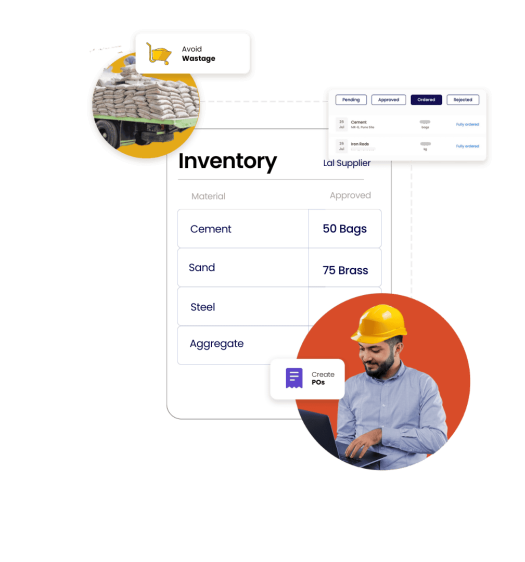

Integrate Production With Inventory & Budgets

Every production run automatically updates material stock and contributes to project cost monitoring — ensuring full financial visibility.

Why Construction Companies Choose Onsite Production Management Software

Eliminate guesswork in on-site production

Define approved material mixes (e.g., concrete grades, plaster ratios) and ensure every batch follows the same proportions. Standardized recipes help maintain consistent quality across sites and reduce rework caused by mix variations.

Track what goes into every batch

Record material inputs and outputs for each production batch or day. Batch-level records create traceability for production activities, making it easier to review consumption, investigate issues, and maintain accountability on site.

Identify wastage before it becomes a loss

Compare planned material usage with actual consumption for every batch. Visibility into deviations helps teams detect over- or under-consumption early, reduce material wastage, and improve production efficiency.

Keep stock accurate and costs under control

Automatically update inventory based on production activity and understand how material consumption impacts project costs. Linked production and inventory data ensures accurate stock levels and supports better cost control decisions.

FAQs on Onsite Construction Production Management Software

What is Onsite’s Construction Production Management Software?

It is a digital system that helps construction companies manage material mixes, record batch production, track consumption, and monitor production efficiency in real time.

Who needs production management software in construction?

Contractors, developers, EPC firms, and industrial companies that handle concrete batching, plaster mixes, fabrication, or any form of in-house production benefit from it.

What problems does Onsite solve in production management?

It eliminates inconsistent material mixes, manual documentation errors, hidden material wastage, and the lack of linkage between production cost and project budgets.

Does Onsite support concrete and mortar production tracking?

You can define concrete grades (M10, M20, etc.), mortar ratios, plaster mixes, and log daily output with complete transparency.

How does Onsite track material consumption?

Onsite records the planned vs actual consumption for each batch and automatically highlights deviations to detect wastage.

Is Onsite’s production module linked to inventory?

Every production run automatically updates material stock in the inventory module to maintain accurate real-time stock levels.

Can Onsite track production cost impact on project budgets?

Absolutely. Production data directly connects with project budgeting, helping companies understand cost overruns early.

Does Onsite support batch-wise and daily production logs?

Yes. Teams can record production on a per-batch, per-shift, or per-day basis with complete traceability.

How does Onsite help improve production quality?

Standardized material mixes, accurate input-output tracking, and digital oversight ensure consistent quality and reduce rework.