How Poor Equipment Tracking Delays Construction Work?

In construction, we track materials and labor but forget the machines doing the real heavy lifting. Whether it’s an excavator parked for hours or a mixer that vanished between sites, unmanaged equipment quietly eats into your profits. Construction Equipment Management Software helps you change that. Using construction equipment tracking software helps teams track, maintain, and optimize every machine on the job. Track where your machines are, how they’re being used, and when they need maintenance with Onsite. From cranes to concrete cutters, you’ll know what’s working, what’s not, and what needs your attention. Because when your equipment runs right, so does your project. This software works as part of a fleet management system to provide real-time visibility into heavy assets across sites.

Why Equipment Mismanagement Becomes a Cost Problem?

When you buy or rent equipment, the costs don’t stop there. Costs keep coming in the form of depreciation, maintenance, and downtime. Traditional tools make it hard to spot issues before machines break down. A construction equipment maintenance software automates oversight and reduces downtime.

When equipment isn’t kept track of correctly:

- Tools go from one location to another without any paperwork, and they regularly go missing.

- It’s not obvious who is responsible for the condition or use of assets.

- Maintenance is put off until something breaks down.

- Idle machinery keeps losing value without adding any.

These gaps might not show up right away in reporting, but they slow down work and lower margins over time. Without tech like fleet tracking software, managers rely on delayed reports that miss daily equipment issues.

What is Construction Equipment Management Software?

Construction equipment management software is a digital system that helps contractors and project teams track, schedule, maintain, and make better use of machinery and tools across one or more job sites.

Think of it as a centralized platform that ensures:

- Every piece of equipment is accounted for

- Better support for decision making

- Equipment is assigned efficiently

- Downtime and overuse are minimized

Common Equipment Issues Seen on Sites

Most construction teams encounter the same challenges repeatedly. Equipment that are mentioned available are not actually available on site. Small tools are nowhere to be found. Schedules are often out of sync, so big equipment sit about doing nothing. Repairs get approved quickly, which messes up scheduled work. When data are missing, it’s hard to tell if delays are caused by misuse, bad scheduling, or missed service.

These problems are not caused by a lack of effort on site. They occur because tracking relies on memory, phone calls, and handwritten records instead of solid ones.

The Equipment Lifecycle and Where Problems Begin

Every asset follows a similar cycle on construction projects:

- Allocation to a project or team

- Daily use on site

- Wear and tear requiring service

- Repair or maintenance

- Movement to another site or return

Losses and inefficiencies usually occur at the handover points. Without a system that records these transitions, control weakens at each stage.

How Equipment Management Works with a Structured System?

With the structured system you can always be aware of where the equipment is, if it is available, if it is under maintenance, if it is assigned on some other site, etc, all with clear records and their updated status.

The data of usage of any equipment can also help teams understand the utilization pattern of the equipment. Any downfall in the performance of the equipment can aware you if it needs maintenance. It saves you from bigger expense and also saves your time. With this approach, decisions are based on records rather than assumptions. Heavy equipment maintenance software lets you schedule services before failures occur.

How Onsite Construction Equipment Tracking Software Supports Asset & Equipment Management?

Real-Time Equipment Tracking

Instead of guessing status, construction equipment tracking software shows live location, usage and condition of every machine on each project. You won’t have to guess where your machines are anymore. With centralized data from all your sites, you can tell right away if equipment is being used, is idle, or is down for maintenance. With equipment fleet management software, organizations reduce breakdowns, extend asset life and protect site productivity.

Utilization Reports

Find out which machines are doing their jobs, and which ones aren’t. Use real facts to make better decisions about renting or buying. You can use reports to see which equipment needs to get repaired or which one is performing at a slow rate.

Assignment & Scheduling

Give the proper site or person the right equipment without any trouble. Don’t schedule the same thing again or change your plans at the last minute. Teams can access data on the go through an equipment management app with real-time updates.

Document Storage

Upload and access service records, manuals, and inspection reports anytime you need them. You don’t have to look through emails or drawers anymore. You can also download the reports of how much equipment has been used at a particular time. You can see how much fuel or diesel has been used.

Notice Idle Equipment

You can see if a machine has been sitting for too long or is being pushed too far. Take care of your investment and your schedule.

Manual Methods vs Structured Construction Equipment Tracking Software

| Area | Manual Methods | Structured System |

|---|---|---|

| Asset visibility | Limited | Centralized |

| Usage logs | Irregular | Consistent |

| Maintenance planning | Reactive | Preventive |

| Location tracking | Manual | Reliable |

| Accountability | Weak | Clear |

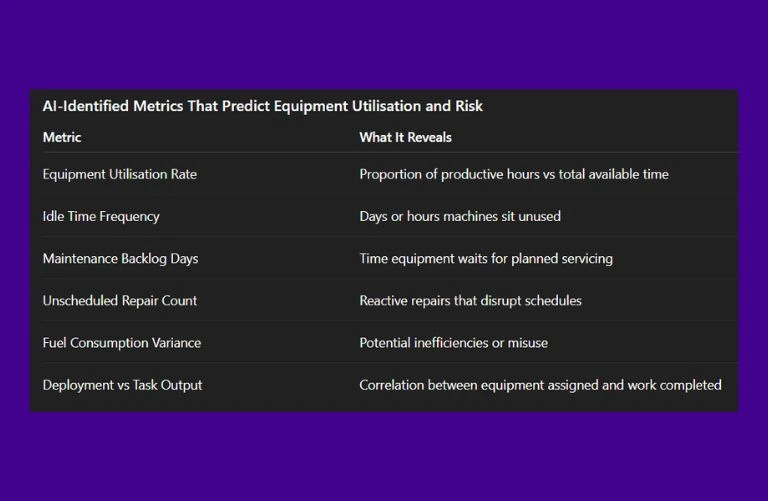

What AI Observes About Construction Equipment Management Metrics?

To understand which performance indicators, matter most when tracking equipment and assets on construction sites, we asked AI to analyze execution data from diverse projects.

Conclusion

Managing machinery with Excel sheets and memory just doesn’t work anymore in today’s fast-paced projects. Construction Equipment Management Software isn’t a luxury; it’s a wise choice for any business that wants to cut down on waste, downtime, and make sites work more smoothly. Stop guessing and start controlling your assets with construction equipment management software and next-generation fleet and maintenance tools. If you have to move machines between different sites, the chances of downtime, missing maintenance, or misplaced tools go up quickly. You may get back control with the correct software, which might save you lakhs in missed work, maintenance, and delays. Discover how fleet and maintenance insights from construction fleet management software help optimize operations across job sites.

Want to manage asset & equipment in a structured way?

FAQs

Construction equipment management software is a tool designed to help teams track, maintain, and organize heavy machines and tools on site, helping you manage them more efficiently.

Construction fleet management software centralizes maintenance schedules, usage history, and service needs so you can prevent breakdowns and reduce downtime for your machines.

Yes. Heavy equipment maintenance software helps you log servicing, plan preventive work, and keep all maintenance data in one system so machinery stays in good condition.

Construction equipment tracking software gives real-time visibility into where machines are, how they’re being used, and when they need servicing, making manual logs obsolete.

Fleet maintenance tracking software helps record equipment health, schedule service intervals, and monitor outcomes, which leads to better planning and fewer costly repairs.

Yes. An equipment management app lets field staff update status, report issues, and view maintenance history right from the job site.

Equipment maintenance software helps you stay proactive with servicing, reduce unexpected repairs, and track costs related to machine upkeep, which improves overall cost control.

Many solutions are built to connect with a wider fleet management system or fleet management app, giving you a unified view of assets and maintenance across all sites.

Fleet monitoring gives supervisors’ up-to-date status on machine performance and health so they can make better decisions about service and deployment.

Yes. Heavy equipment fleet management software scales to handle both large construction fleets and small fleets.