Cement Rates in India are rising exponentially in the last 10 years. There has been a great hike in the cement pricing trends after the outbreak of covid 19. Increased coal rates, devaluation of Indian currency, transportation costs, and government policies are some attributing factors responsible for the hike in cement rates. As a result, there has been a significant increase in the real estate values in India. Therefore it is important to find a high-strength cement that is cost-effective at the same time. Here is a guide to let you choose an apt cement that is best suited for your construction needs.

Cement is a raw material used in the construction industry which serves binding purposes. Cement plays a significant role in construction. It is used for concrete build-up, masonry, plastering, tiling and roofing. It reacts exothermically with water and hardens on cooling. It has high tensile strength and when properly fabricated provides high strength to the building structures.

Mostly Used Cement Types In India

1- OPC (Ordinary Portland Cement)

It is the most widely used cement for construction. It provides high strength and durability to the building structure. It comes in three grades depending upon its strength. These are 33 grade OPC, 43 Grade OPC and 53 Grade OPC. 53-grade provides the highest strength and is used for RCC construction and multi-story buildings. 43-grade OPC is used in procedures where strength is not the major concern, for example, plastering, tiling the floor, roofing, etc. 33-grade cement has the least strength and is rarely used in any construction processes.

2- PPC (Portland Pozzolana Cement)

It is a high-strength cement which is impervious to water. It is used for the construction of hydraulic structures like dams, marine works, etc. It has a high setting time, therefore, radiates less heat and increases workability. Its strength is equivalent to 53-grade OPC. It is the ideal cement for extreme conditions. Due to its impermeability and high workability, it is nowadays preferred over 53-grade OPC for concrete constructions.

3- White Cement

It is usually used for repairing purposes or as fillers in tiles and marbles. It has low strength and is used for wall finishing and making decorative interiors and exteriors.

Also Read: Green Cement Revolution: Environmentally Friendly Options and Their Prices in India

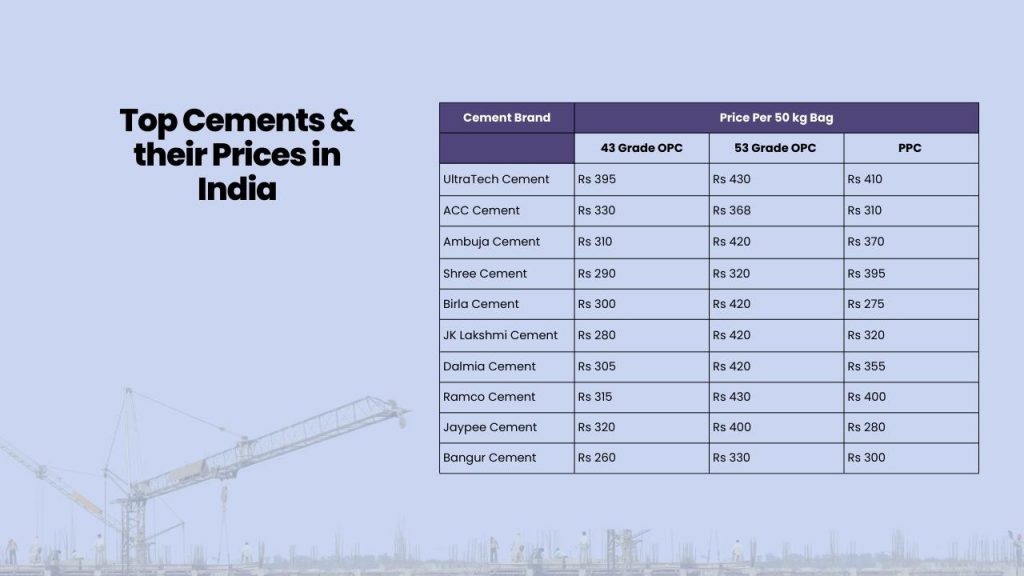

Cement Prices in India (June 2023)

Here we are comparing the cement prices of different cement types from some of the top cement brands in India with UltraTech leading the way.

Cost-Saving Strategies for Contractors

1- Compare Prices

Before making a purchase, compare prices from different suppliers or retailers. Research and obtain quotes from various sources, including local cement dealers, authorized distributors, and online platforms. This will give you a better understanding of the prevailing market rates and help you identify the best deals.

2- Buy in Bulk

Purchasing cement in larger quantities can lead to significant cost savings. Negotiate with suppliers to obtain discounted rates when buying in bulk. Bulk purchases not only save money but also ensure a consistent supply, reducing the risk of running out of cement during your projects.

3- Assess Quality

While price is important, prioritize the quality of cement. Always choose reliable and reputed brands that adhere to industry standards. Poor-quality cement can result in structural issues and additional expenses in the long run. Research different cement brands, their manufacturing processes, and customer reviews to make an informed decision.

4- Select the Appropriate Grade

Cement in India is available in various grades such as OPC (Ordinary Portland Cement) 43 and 53, PPC (Portland Pozzolana Cement), and PSC (Portland Slag Cement). Assess your project requirements and consult with structural engineers or architects to determine the appropriate cement grade. Choosing the right grade helps you avoid unnecessary expenses without compromising on quality.

5- Purchase Directly from Manufacturers

In some cases, purchasing cement directly from manufacturers can be cost-effective. Identify cement companies with manufacturing plants near your project site and inquire about their direct sales options. This approach eliminates middlemen and associated markups, allowing you to obtain cement at competitive rates.

6- Utilize Seasonal Discounts & Offers

Keep an eye out for seasonal discounts, festive offers, or promotional schemes provided by cement manufacturers and suppliers. Many companies introduce special pricing during specific periods to boost sales. By taking advantage of these opportunities, you can save money on your cement purchases.

7- Proper Storage and Usage

Ensure proper storage and handling of cement to avoid wastage and deterioration. Store cement bags in a dry area, away from moisture and direct sunlight, to maintain their quality. Follow recommended usage guidelines and avoid overmixing or unnecessary cement consumption during construction. By minimizing wastage, you can maximize your savings.

Conclusion

In conclusion, contractors must stay updated on the latest cement rates in India to effectively manage project costs. By understanding the factors that influence cement prices and implementing money-saving tips, contractors can optimize their budget and maximize profitability. Strategies such as exploring bulk purchase options, considering alternative cement types, and negotiating with suppliers can help contractors save money without compromising quality. It is crucial to stay informed, adapt to market dynamics, and make smart decisions when navigating the fluctuating cement rates in India.