BOQ vs Budget vs Actual: What Contractors Get Wrong

It is a common misconception between contractors that cost overruns are a result of rising prices of material, labor, shortages, and client-driven changes. Things start to slip out of hand even before it has been realized. BOQ vs budget vs actual costs are handled as three separate exercises, and they all have been maintained by different teams with different digits. By the time you see a blunder in any of them, the damage has already been done and cannot be rectified. This is the reason why it is important to examine how each element is used in real projects and why learning the right way to manage construction projects is important.

Understanding the Three Numbers: BOQ vs Budget vs Actual

Clear definitions are the first step to clarity. Without that base, every comparison of statistics is wrong from the start.

BOQ: The Planned Scope of Work

A BOQ lists the amounts and rates for specific types of work. It is not its job to guess how much the project will cost; its job is to make the measurement and scope clear. In short, it answers one simple question.

How many of each item are expected to be made?

The BOQ is a guide for planning and keeping things in check. Once work starts, it doesn’t show how much money is being spent or how well things are going.

Budget: The Financial Expectation

The budget changes the quantities in the BOQ into the estimated costs of the project. It combines costs for labor, materials, subcontractors, overhead, risk, and profit.

It solves a very other question.

If everything goes according to plan, how much should this project cost?

Actual: The Reality on Site

Actuals show what really happens when something is done. They are made using confirmed site data such completed quantities, labor attendance, productivity, material usage, and approved progress reports.

Actuals answer the most crucial question of all.

What did we really do and spend?

Most contractors keep note of all three numbers. Things start to go wrong since these numbers don’t often connect. When they are alone, control decreases, and decisions are based on incomplete knowledge instead of the whole picture.

How BOQs Lose Their Purpose After Tendering?

When making an estimate, the BOQ is carefully put together. Rates are negotiated, quantities are checked, and margins are built in. But after execution starts, the BOQ is no longer used every day.

While construction is going on, site teams don’t often talk about BOQ items. Engineers are focused on getting things done. Supervisors keep track of labor and materials based on what is available, not on what was intended. People only open the BOQ when they need to bill or make a claim for a change over time.

At that point, it doesn’t help with execution anymore. Instead of being a tool that helps people make decisions every day, it becomes a historical chronicle. A document instead of a real-time control tool that affects daily choices.

Why Budgets Become Broad and Unreliable?

Budgets are always derived or taken out from the BOQs but is it always in a structured way? Costs are regrouped into broader heads such as civil work, finishes, MEP, or overheads which is really great for accounting but does it help in site control? When the budget is not tracked deeply, it can be slowly eaten up little by little until by the end of the project it goes over budget. Many things go unnoticed like overordering of material, labor being absent but marked present, equipment sitting ideal, and payments spikes. The budget exists, but it no longer reflects how work is actually progressing.

Why Actual Costs Rarely Tell the Full Story?

Actual cost is tracked through the accounts. Bills are only entered after the approvals. Labor payments are processed monthly. Site expenses are posted once supporting bills arrive.

The delays above mentioned are dangerous and costly.

When the time comes to review the actuals, the site has already been one and moved on and there is nothing you can do to save your money. There is no link between the plan, execution, and payments. Your reports can be accurate but, in this case, it is not giving you any clarity or transparency. There are no explanations of overbudgets. Without context, numbers only confirm a problem. They do not help prevent it.

The Core Mistake Contractors Make

The main issue is separation.

- The BOQ sets the limits.

- The budget sets the goal.

- The results are shown by the actuals.

When these parts work separately, control becomes reactive. Owners rely on calls. Managers waste time looking for answers. Site teams don’t really know how their work affects the budget.

Controlling costs isn’t something you do at the end of the month. For contractors, it only works if they make it a daily habit.

Why Linking BOQ, Budget, and Actual Changes Control

When BOQ, budget, and actual figures share the same structure, every site activity has financial meaning.

When tasks are created directly against BOQ items, every progress update shows how much of the scope has already been used. When budgets stay tied to those same items, deviations become visible at the point where they start, not later in reports.

If actual costs and quantities are recorded on site and linked to tasks, overspending appears early, while corrections are still possible. Control moves closer to the site, where day-to-day decisions are made, instead of sitting only in the office.

How the Linkage Works on Live Projects?

The process itself is simple.

- BOQ items are prepared with clear quantities and units.

- Budgets are set against those same BOQ items.

- Daily progress records capture what is actually executed against them.

- Labour and material entries attach directly to daily execution.

- Actual costs then build steadily from verified site data.

Because deviations appear early in this flow, teams can correct course while there is still time, instead of discovering the impact after losses have already grown.

How Onsite Fits Into BOQ vs Budget vs Actual Control?

Onsite is specifically made for construction projects. It has been made by keeping a keen eye on every small thing that happens at construction sites or projects. Onsite is built with the thought that construction control must happen during execution, not after it.

In Onsite, BOQ is not treated as a static document. Each BOQ item becomes the base for tasks, budgets, and tracking. Site activities are planned against defined quantities instead of rough assumptions.

To maintain consistency in planning as well as execution, Onsite makes budgets flow directly from the BOQ items. Labour, materials, subcontract costs, and expenses are monitored against the same structure used during estimation.

Actuals are recorded precisely where the work is done. Every day, the number of workers, the cost of materials, and the cost of the site are all documented and linked to the tasks and BOQ items. The data show what really happened on the site, not summaries that were delayed or changed.

Instead of having to compare three different reports, contractors can see planned quantities, budgeted costs, and actual performance all in one platform. This way to manage construction projects is better than the traditional one.

The Practical Impact on Projects

The Shift That Makes the Difference

It is often confusing to contractors how they lose their money. It is not because they lack documents but because the documents do not provide them with the updates of daily actions. Treating BOQ, budget, and actual as one continuous system brings discipline to execution. It replaces assumptions with visibility and replaces late surprises with timely course correction. That change is more important than any one report or review meeting. It is frequently what keeps a project on track or slowly pulls it off course. This how you can manage construction projects effortlessly.

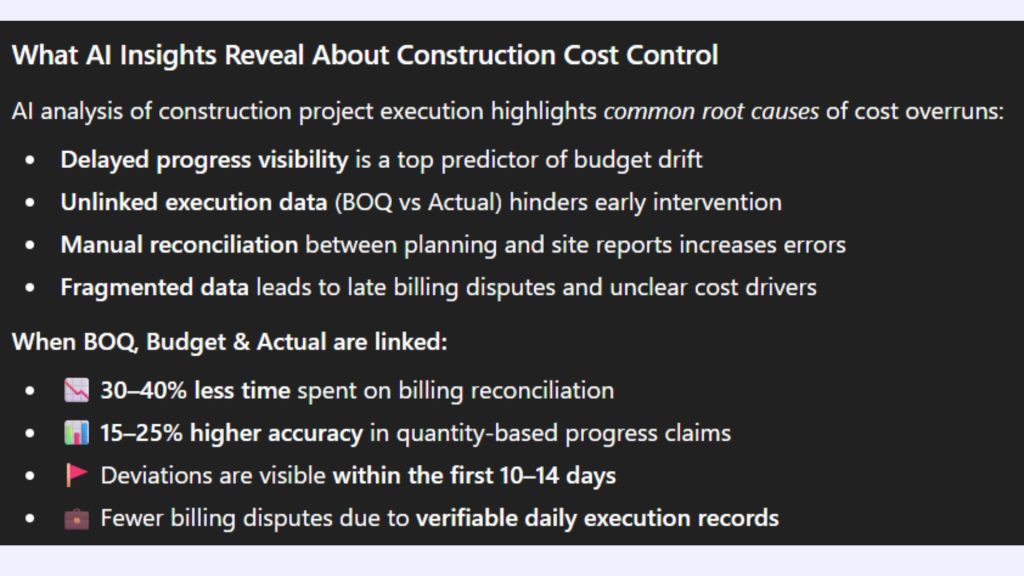

What AI Insights Reveal About BOQ–Budget–Actual Linkage?

Want to maintain your bugets to avoid losses?

FAQs

1. What is the main difference between BOQ, budget, and actual cost?

A BOQ defines the scope and quantities of work with rates. The budget sets the planned spending limits based on that scope. Actual cost reflects what has been spent on labour, materials, subcontractors, equipment, and expenses during execution. Problems arise when these three are maintained separately instead of working as one system and it becomes much more about BOQ vs Budget vs Actual.

2. Why do contractors lose control even when they have a BOQ and a budget?

Because both documents are often disconnected from daily site activity. The BOQ stays as a tender or billing reference. Budgets are tracked at a broad level. Site decisions are made without real-time financial feedback. Control slips not due to lack of data, but due to lack of linkage.

3. Is tracking actual cost through accounting software not sufficient?

Accounting data shows what has already been paid, usually with a delay. It rarely explains which activity caused the overspend or whether it could have been avoided. Without linking costs to tasks and BOQ items, accounting reports remain backward-looking.

4. At what stage should BOQ items be used on site?

From the first day of execution. BOQ items should guide task planning, quantity tracking, material consumption, and progress measurement. When site teams work against BOQ-defined scope, deviations become visible early.

5. How does linking tasks to BOQ improve budget control?

When tasks are tied to BOQ quantities, progress updates automatically reflect how much scope has been consumed. Budget overruns are seen against specific items instead of generic cost heads, making corrective action practical.

6. Why is daily tracking more effective than weekly or monthly reviews?

Construction problems develop daily. Labour productivity, material wastage, and sequencing issues do not wait for review meetings. Daily tracking catches small deviations before they turn into major overruns.

7. How does Onsite help manage BOQ vs budget vs actual together?

Onsite connects BOQ, planning, budgets, and site data into one execution flow. BOQ items become the base for tasks and budgets. Labour, materials, and expenses are recorded daily and linked back to those same items. This keeps planned, budgeted, and actual figures aligned at all times.

8. Can this approach help with faster billing and variations?

Yes. When quantities executed are already tracked against BOQ items, billing becomes easier to verify. Variations are supported by recorded data rather than site memory or post-facto measurement.

9. Does this replace accounting software like Tally or Zoho?

No. Accounting systems handle statutory reporting and compliance. Onsite helps you manage construction projects by focusing on execution control. When actual site data is structured and accurate, accounting entries become cleaner and easier to reconcile.

10. What is the biggest mindset change contractors need to make?

Shifting cost control from a monthly accounting exercise to a daily site discipline. Projects stay profitable when decisions are guided by real-time data, not end-of-month summaries.