TMT Bars, also known as Thermo Mechanically Treated Bars, play a crucial role in construction projects by providing the necessary strength and durability to withstand various forces. Using high-quality TMT bars is essential to ensure the safety and longevity of the structure. In this blog, we will discuss the types and grades of TMT steel bars, as well as their applications. We will also provide links to buy some of the best TMT bars available in India, which top contractors trust for their quality and reliability. Whether you’re a contractor or an individual looking to build your dream home, this blog will provide you with valuable information on the best TMT bars in India.

TMT means “Thermo Mechanically Treated” these bars contain a solid exterior and a soft interior. TMT bars are used in many construction industry sectors, such as residential/commercial buildings, bridges, industrial constructions, and concrete reinforcement. The main advantage of TMT, which outperforms its alternatives, steel bars, is that TMT bars are immune from corrosion damage. Here’s the list of the Best TMT Bars in India.

Best TMT Bars in India

In construction projects in India, two primary types of TMT bars are used

1) Low-Ductility Bars

Low-ductility TMT bars are known for their high strength but lower elongation properties, making them more brittle compared to high-ductility TMT bars. They can withstand higher stress than high-ductility bars, but they have a lower resistance to deformation. Typically, these bars are used in construction projects where ductility is not a primary concern, and the structure is not expected to experience significant stress due to temperatures or seismic activity, such as flyovers, bridges, and other buildings.

Manufacturers can produce low-ductility TMT bars by using a higher percentage of carbon and other alloys in the manufacturing process to enhance their strength, making them more cost-effective than high-ductility TMT bars. However, low-ductility TMT bars have a higher risk of sudden failure in the event of an earthquake or other severe environmental stresses. Therefore, engineers and contractors must carefully evaluate the specific requirements of a project before selecting the type of TMT bars to use, ensuring the safety and longevity of the structure.

2) High-Ductility Bars

High-ductility TMT bars, also known as earthquake-resistant bars, possess superior elongation and ductility properties compared to low-ductility TMT bars. These bars can withstand higher deformation and stress due to seismic activity, making them an excellent choice for structures located in earthquake-prone areas.

Manufacturers enhance the ductility of these bars by adding certain elements, such as copper, during the manufacturing process. The ductility of these bars helps absorb the energy generated during an earthquake or other environmental stress, preventing sudden failure and collapse of the structure.

High-ductility TMT bars are typically used in critical infrastructure such as hospitals, schools, and high-rise buildings, where safety is of utmost importance. While high-ductility TMT bars have slightly lower strength than low-ductility bars, this difference in strength is negligible and can be compensated by using larger diameter bars or adding additional bars to the structure.

What is earthquake resistant TMT Bars?

Earthquake resistant TMT bars are made as reinforcement bars that have ductility, strength, and other properties that are necessary to withstand the stresses and strains caused by seismic activity.

If we talk about the key features of earthquake resistant TMT bars then some of them are high ductility, high yield strength, enhanced elongation, superior bonding with concrete, and corrosion resistance. The advantages of using these TMT are that it improves safety, offers high structural integrity, and it is cost effective.

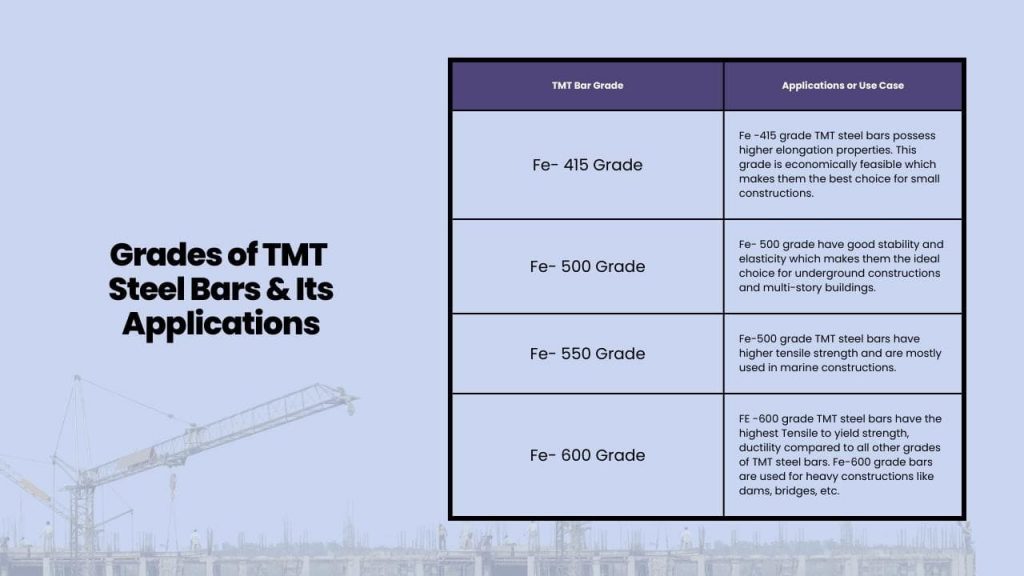

Grades of TMT Steel Bars & Its Applications

Apart from these two types of TMT bars, various grades of TMT steel bars are available, including Fe 415, Fe 500, Fe 550, and Fe 600, each with varying levels of strength and ductility. The appropriate type and grade of TMT bars are chosen by engineers and contractors based on the specific requirements of the project, ensuring that the structure is strong, durable, and safe.

In India, TMT bars are available in various grades that determine their strength, durability, and ductility. The Bureau of Indian Standards (BIS) regulates the quality and standards of TMT bars in India and defines these grades. These different grades indicate the strength & rigidity factor of the steel bar. The numbers indicate the force that must be applied to deform or modify the steel bars for various purposes.

Fe-415, Fe-500, and Fe-550 are the most commonly used grades of TMT bars in India. The numbers in these grades denote the yield strength of the bar in megapascals (MPa), with Fe indicating iron. Fe-415 has a yield strength of 415 MPa and is suitable for use in small to medium-sized constructions like houses and low-rise buildings.

Fe-500, with a yield strength of 500 MPa, is more durable and resistant to corrosion and is used in larger construction projects such as high-rise buildings, bridges, and industrial structures. Fe-550, with a yield strength of 550 MPa, is the strongest grade of TMT bars available in India and is primarily used in heavy construction projects such as dams, bridges, and high-rise buildings. Additionally, higher grades of TMT bars like Fe-600 and Fe-650 are used in special construction projects requiring high strength and durability.

What are 550d TMT bars for construction?

The 550D TMT bar is a kind of high-strength reinforcement bar that is used in construction , particularly in reinforced concrete structures. The 550 in 550D showcases the yield strength of the bar in MPa (megapascals). This basically indicates the amount of stress TMT can take whereas D stands for ductility. The higher the ductility, the more strength a steel has to undergo significant plastic deformation before rupture.

Link to Buy Some of the Best TMT

These are some of the best TMT Bars available in the Indian market. Below you can find the product name and their buying link

We are availing some of the best companies and their buying link in the following section. These are some of the best companies that avails TMT Bars in the Indian market.

1) Tata Tiscon 550 SD

Tata Tiscon is one of the most trusted steel company out there. It has India’s first GreenPro certified rebar manufacturing. With many other features, it is a reliable company.

Buying link – https://tatatiscon.co.in/

2) Jindal Panther Fe 550 D TMT Bars

Jindal Panther, with continuous innovation and better technology, is one of the best-known steel manufacturers out there.

Buying link – https://shop.jindalpanther.com/

3) JSW Neosteel 550D

JSW manufactures steel with sustainable practices, and it is one of the leading steel suppliers in India.

Buying link – https://www.jswneosteel.in/

4) Radha TMT 550 D LRF

Radha groups avails some of the best and top-notch steel products in Indian construction industry.

Buying link – https://www.radhatmt.com/

5) JYOTI Tempcore SG Rebars

JYOTI Tempcore SG Rebars is one of the growing steel suppliers and manufacturers in India. They provide best quality steel products.

Buying link – https://www.madhavkrggroup.com/tmt-bars.php

6) Prime Gold TMT

Prime Gold being the leading steel manufacturer in India that avails high-end quality products.

Buying link – https://www.primegoldgroup.com/

7) SAIL TMT

SAIL, being one of the largest steel manufacturing companies, offers high quality steel products in India.

Buying link – https://www.sail.co.in/en/products/sail-tmt

8) Vizag TMT 500D

Vizag Steel has the very first shore based Integrated steel plant in India. It offers top-grade steel products.

Buying link – https://www.vizagsteel.com/index.asp

9) Kamdhenu NXT

Kamdhenu uses cutting edge technology to produce steel products. It offers superior steel products.

Buying link – https://www.kamdhenulimited.com/kamdhenu-nxt-tmt-bars.php

Also Read: https://www.elegantsteels.com

Factors to Consider While Buying TMT Bars

When it comes to purchasing TMT bars in India, several factors need to be considered to ensure the quality and strength of the construction. Some of these factors are:

Brand Reputation

It’s important to choose a reputable brand that has a proven track record of delivering high-quality TMT bars.

Grade of TMT

The grade of TMT bars required for a project depends on the specific requirements of the construction, such as the load-bearing capacity and seismic zone.

Certification

Look for TMT bars that are certified by BIS (Bureau of Indian Standards) or other reputed certification agencies to ensure the quality of the product.

Corrosion Resistance

Check the TMT bars for their ability to resist corrosion, especially if the construction is located in a coastal area or exposed to moisture.

Bendability

The TMT bars should have the required bendability for easy shaping during construction.

Price

While the price of TMT bars is an important consideration, it should not be the only deciding factor. Cheaper TMT bars may compromise on quality and strength, which can lead to long-term issues.

Availability

Choose a supplier who can provide a consistent supply of TMT bars throughout the duration of the construction project.

Also Read: Latest Steel Rates Today In India | TMT Steel Price Today

Conclusion

In conclusion, selecting high-quality TMT bars is crucial for ensuring the safety and longevity of structures in the construction industry. With a wide range of TMT bars available in India, it is important to choose the best TMT bars that are suitable for your project. In this blog, we have discussed the different types and grades of TMT steel bars, as well as their applications.

Additionally, we have provided links to purchase some of the best TMT bars in India that are trusted by top contractors for their quality and reliability. Whether you are constructing a residential or commercial project, selecting the right TMT bars can make a significant difference in the overall strength and durability of the structure. Therefore, it is important to carefully choose the best TMT bars for your project to ensure its safety and longevity.

FAQs

1 What are TMT bars and why are they important in construction?

TMT bars are necessary part of construction projects as they provide the needed strength and durability to bear various forces. They are famous for providing a solid exterior and soft interior which makes them resistant to corrosion. It is suitable for usage like residential/commercial buildings, bridges, and concrete reinforcement.

2 Name the primary types of TMT bars used in India for construction projects?

There are two types of TMT Bars named low-ductility bars and high-ductility bars. While Low-ductility bars offer high strength and lower elongation properties, high ductility bars offer earthquake resistance and they possess superior elongation and ductility properties.

3 What grades of TMT bars are available in India and how are they used in construction?

There are different types of TMT bars available in India including Fe 415, Fe 500, Fe 550, and Fe 600. Each type of TMT bar offers a different level of strength and ductility. They all are made for different construction projects like high-rise buildings, bridges, and industrial structures.

4 What are the best TMT bars available in India?

By trusted quality and reliability, there are some best TMT bars available in India including Elegant Steel, Tata Tiscon 550 SD, Jindal Panther Fe 550 D, JSW Neosteel 550D, Radha TMT 550 D LRF, JYOTI Tempcore SG Rebars, Prime Gold TMT, SAIL TMT, Vizag TMT 500D, and Kamdhenu Nxt. These TMT bars can be purchased from reputable suppliers and manufacturers through their official websites or authorised distributors.

People also search for: best tmt bar in india for house construction, best tmt bar in india, which tmt bar is best for house construction, which tmt bar is best, best tmt steel for house construction, best tmt bars, best steel bars for construction, top tmt bar in india, best iron rod for construction, which brand tmt bar is best for house construction, primary tmt bars in india, best steel bar for house construction, best quality tmt bars in india, which tmt steel is best for house construction