Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Difference Between Rigid Pavement and Flexible Pavement

Transportation infrastructure depends heavily on pavement for smooth and safe vehicular and pedestrian movement. Rigid and flexible pavement are two common types of pavement used in construction. Despite having the same purpose, they differ in composition, design, and performance. A thorough understanding of the distinctions between rigid and flexible pavement is necessary for selecting the appropriate pavement for a particular project. In this blog post, we have discussed the features, benefits, drawbacks, and applications of both rigid and flexible pavement. By the end of this post, you will have a better understanding of which type of pavement suits your specific requirements.

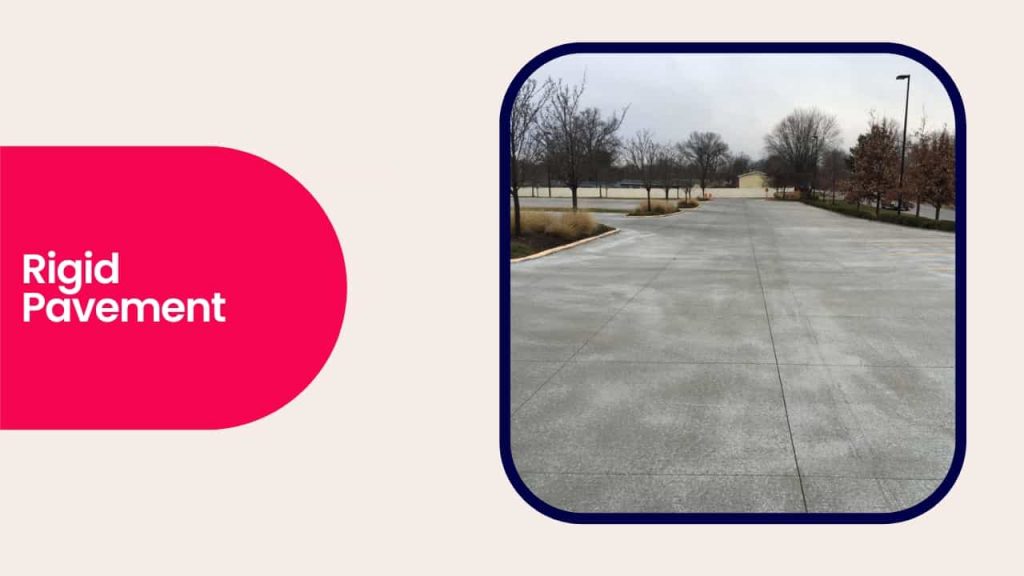

What is Rigid Pavement?

Rigid pavement is a type of pavement made of reinforced concrete slabs used in constructing roads, runways, parking lots, and other heavy traffic areas. Concrete is used to make rigid pavements, providing greater strength, durability, and longevity compared to flexible pavements, which consist of asphalt and aggregate. Steel bars reinforce the rectangular or square-shaped slabs of rigid pavements to increase their strength and reduce cracking. The slabs are laid perpendicular to the direction of traffic. A flexible sealant fills the joints between the slabs, enabling them to move slightly without cracking.

Construction engineers choose to use rigid pavements primarily because they can withstand heavy traffic loads. Concrete is a durable and robust material that can support heavy loads without cracking or deteriorating over time, particularly when reinforced with steel. This makes rigid pavements an excellent choice for high-traffic areas that need a sturdy and long-lasting surface. Furthermore, rigid pavements have a longer lifespan and require less maintenance than flexible pavements, in addition to their strength.

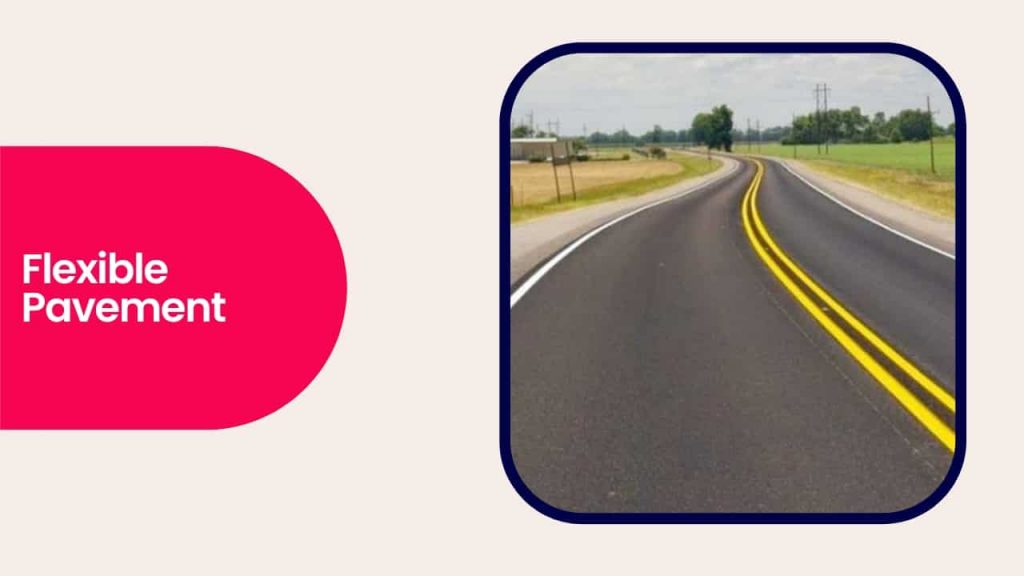

What is Flexible Pavement?

Engineers construct flexible pavements using materials that are flexible or deformable under traffic loads to construct roads or highway pavements. The primary objective of this pavement is to distribute the load from vehicles and safeguard the subgrade from damage. Layers of materials with specific functions are used to build the pavement.

Layers of Flexible Pavements

- Wearing Course: The top layer of flexible pavement is the wearing course, which is designed to resist wear from traffic and weather. It is made of asphalt concrete or other bituminous materials and is usually between 25-50 mm thick.

- Binder Course: The binder course is the intermediate layer between the wearing course and the base course. It is designed to provide additional strength and durability to the pavement and to prevent the intrusion of water into the subgrade. It is usually between 50-100 mm thick and is made of bituminous materials.

- Base Course: The base course is the layer that provides support to the upper layers of the pavement. It is designed to distribute the load from the pavement and to protect the subgrade from damage. It is usually between 150-300 mm thick and is made of materials like crushed stone, gravel, or other aggregates.

- Subgrade: The subgrade is the natural or prepared soil beneath the base course. It is the foundation on which the pavement is built and must be strong enough to support the pavement and traffic loads. The subgrade is prepared by grading, compacting, and stabilizing the soil.

Engineers use bituminous materials, which have a high viscosity, to bind aggregate materials together for constructing flexible pavements. These materials can deform under traffic loads and regain their original shape after the load is removed. The primary advantage of flexible pavements is their ability to distribute traffic loads over a wide area, reducing subgrade stress. As a result, they are well-suited for high-traffic volume and heavy load areas like highways and airports. The materials used to construct flexible pavements are flexible, allowing them to adapt to varying subgrade conditions and provide a stable and smooth driving surface for vehicles.

In addition, flexible pavements are a more cost-effective option for many projects since they have a lower initial cost than rigid pavements. They also require less maintenance and can be easily repaired using simple patching methods. This reduces the maintenance and repair costs over the pavement’s lifespan. Moreover, flexible pavements are more resistant to temperature changes and can expand and contract without cracking or deteriorating, making them ideal for areas with extreme weather conditions.

Difference between Flexible & Rigid Pavements

- Construction: Engineers construct flexible pavements using multiple layers of flexible materials, while rigid pavements are built using a single layer of rigid material.

- Materials: Engineers use bituminous materials for constructing flexible pavements, while rigid pavements are constructed using concrete or other rigid materials.

- Behavior under traffic loads: Flexible pavements distribute traffic loads over a wide area, reducing the stress on the subgrade, while rigid pavements transfer traffic loads directly to the subgrade.

- Performance: Flexible pavements perform well in areas with high traffic volumes and varying weather conditions, while rigid pavements are better suited for areas with low traffic volumes and stable subgrades.

- Maintenance: Maintaining and repairing flexible pavements is easier compared to rigid pavements, as they can be patched or resurfaced more easily. Repairing rigid pavements requires specialized equipment and techniques, and they may need to be completely replaced if damaged.

Conclusion

To make a decision between flexible and rigid pavements, various factors such as traffic volume, climate, and subgrade stability must be considered. Flexible pavements are suitable for areas with high traffic volumes and varying weather conditions. They are easier to maintain and repair as they can distribute traffic loads over a wide area. Rigid pavements, on the other hand, are better suited for areas with low traffic volumes and stable subgrades. They can withstand heavy traffic loads without deteriorating and have a longer lifespan. The ultimate decision on the type of pavement should be made after careful consideration of these factors to ensure the safety and durability of the road or highway.

Try Onsite, #1 Tool For Site Tracking