Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Free Steel Weight Calculator For One Way Slab

Welcome to our One-Way Slab Steel Calculator – a robust tool crafted to simplify and optimize steel weight calculations for one-way slabs, with a specific focus on the Indian construction context. This intuitive calculator ensures efficiency and accuracy in planning steel reinforcement. In this example, we guide you through a step-by-step procedure, covering assumptions, calculations, and the final steel weight result. The calculator strategically places main and distribution bars for the longer and shorter spans of the slab, adhering to transparent assumptions and local standards. Accessible to users with varying levels of expertise, this tool empowers your construction projects with precision

How to Use Steel Calculator for One Way Slab

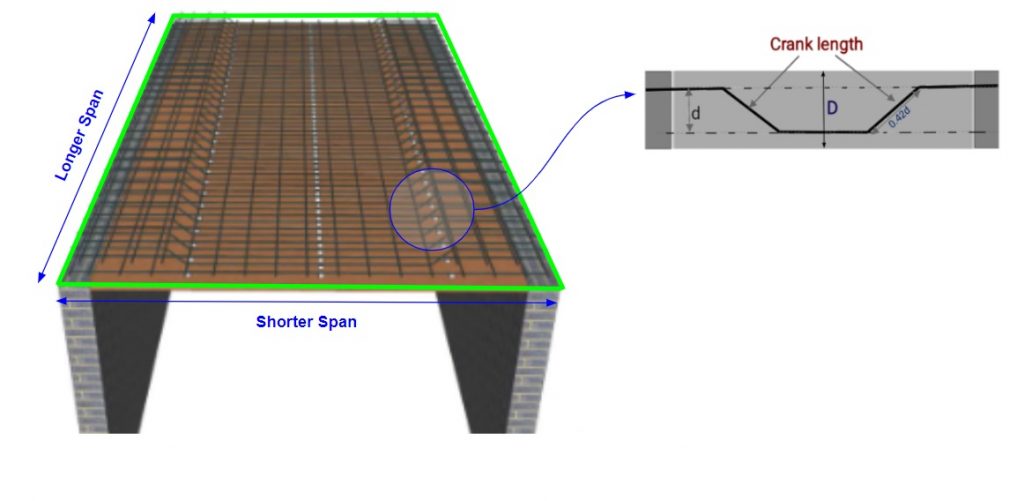

Let’s understand with the help of an example, how to use the above Steel Calculator for Slab. Distribution bars are provided in the longer span of the

one-way slab & main bars are placed along the shorter span of the slab.

Assumptions for Example

- There are 2 types of bars in one way slab: Main Bar & Distribution Bar

- Main Bar Diameter = 10 mm

- Spacing Between Main Bars(C/C distance) = 150 mm

- Distribution Bar Diameter = 8 mm

- Spacing Between Distribution Bars(C/C distance) = 100 mm

- Length of Slab = 6000 mm

- Width of Slab = 3000 mm

- Width of Beam of Slab = 300

- Concrete Cover = 25 mm

- Slab Thickness = 150 mm

- We are using Steel grade of fe500

Calculation Procedure

Step 1: Calculation of total no. of bars

Calculate the number of bars required (main and distribution both).

Number of Main Bars = (Length of Longer Side / Spacing) + 1

=(( 6000/150)+1) = 41

Number of Distribution Bars = (Length of Shorter Side / Spacing) + 1

= ((3000/100)+1) = 31

Step 2: Calculation of cutting length of main & distribution bar

Cutting Length of Main Bar = Clear Span (L) + (2 x Beam Width) – (2 x Con. Cover) + (1 x Inclined Length) – (45° bend x 2)

where L = Clear Span of the Slab ;0.42D = Inclined length (Bend length) ;1d = 45° bends (d is diameter of bar)

First calculate the length of “D“. i.e D = (Thickness) – 2 (Clear cover at Top, Bottom) – Diameter of the bar.

D = 150- 2×25 – 10 = 90 mm

Cutting Length of Main Bar = 3000 – 2×300 – 2×50 + 0.42×90 – 2×10= 2318 mm

Cutting Length of Distribution Bar = Clear Span (Lclear) – (2 x Con. Cover)

= 6000 – 2×25 = 5950 mm

Step 3: Calculation of Top Distribution Bar

Numbers of Top distribution bar for longer span = {(L/4)/spacing + 1} × 2 sides

= ((3000/4)/100 +1) = 9

Cutting Length of Top Distribution Bar = Clear Span – (2 x Con. Cover)= 5950 mm

Step 4: Total Length Calculation

Total Length of Main Bar = 41 x 2318 = 95038 mm = 95.038 m

Total Length of Distribution Bar = 31 x 5950 + 9 x 5950 = 238000 mm = 238 m

Step 5: Calculation of Steel Weight

Weight of the bar as per their length and diameter by following Formula: –

Unit weight formula for kg per metre =(D^2/163) × L kg/m

Unit weight for feet per metre = (D^2 / 533) × L kg/ft

L is the required length of Steel bar of Diameter D

Weight of Main Bar = (102/163) x 95.038 = 58.31 Kg

Weight of Distribution Bar = (82/163) x 238 = 93.45 Kg

Final Result

Total Steel Weight = 58.31 + 93.45 = 151.76 Kg

Uses of Steel Weight Calculator For One Way Slab

- Efficient Reinforcement Planning: Simplify the process of planning steel reinforcement for one-way slabs using a user-friendly calculator designed for clarity and ease of use.

- Quick and Accurate Calculations: Determine the number of main and distribution bars, cutting lengths, and total steel weight efficiently, saving valuable time in your project planning.

- Tailored for Indian Standards: The calculator considers bar types, diameters, and spacing commonly used in the Indian construction industry, aligning with local standards and practices.

- Transparent Assumptions: Clearly defined assumptions for the example provide users with a solid foundation for inputting their specific project parameters.

Best Practices for Steel Weight Calculator For One Way Slab

- Precision in Input Values: Ensure accurate input of values such as bar diameters, spacing, and slab dimensions to achieve reliable calculations.

- Adherence to Assumptions: Understand the assumptions presented in the example and adjust them according to the unique requirements of your project.

- Cross-Verification of Results: Verify the calculated results through manual checks or reference to industry standards to guarantee accuracy.

- Consideration of Real-World Variations: Acknowledge that real-world construction may have variations, and the calculator provides estimates based on specific assumptions.

- Optimal Placement of Bars: Confirm that the calculator’s recommendations align with optimal bar placement guidelines for structural soundness.

- Review of Material Specifications: Confirm that the selected steel grade (fe500) aligns with your project specifications and local building codes.

- Inclusion of Safety Factors: Account for safety factors and consult with structural engineers to ensure the calculated reinforcement meets safety standards.

- Dynamic Project Changes: In the event of significant changes to project parameters, re-run calculations to reflect updated requirements accurately.

- Documentation of Calculations: Maintain a detailed record of calculations for future reference, audit purposes, and collaboration with project stakeholders.

Other Free Important Calculators for you

- Brick Calculator For Wall

- Paint Quantity Calculator

- Steel Weight Calculator For Column

- Steel Weight Calculator For Footing

- Steel Weight Calculator For One Way Slab

- Steel Weight Calculator for Two Way Slab

People also search for: steel quantity calculator for slab, one way slab calculator, steel calculator for slab, slab steel calculator, slab steel quantity calculator, slab weight calculator, slab steel calculation online, one way slab, slab crank length