Construction Production Management Software — Built for Real Project Execution

Create Material Mixes, Manage Fabrication & Control Site Production. For contractors managing in-house fabrication or material batching, production control directly affects project timelines and cost.

Ideal For

01

Infra & EPC Companies

Control concrete, asphalt, or plant-based production with accurate batch and material tracking.

02

Industrial

Firms

Manage fabrication, pre-cast, and production workflows with real-time consumption analytics.

03

Building

Contractors

Run on-site batching and mixing operations with standardized recipes and controlled consumption.

Trusted by 20,000+ Construction Companies Worldwide

Why Construction Companies Need Production Management Software

Inconsistent Material Mixes Affect Quality

Without a standard recipe, material proportions vary from batch to batch — leading to weak concrete, poor plaster finish, or rework.

Manual Recording Causes Hidden Material Loss

Paper logs cannot accurately track how much raw material is consumed vs how much output is produced.

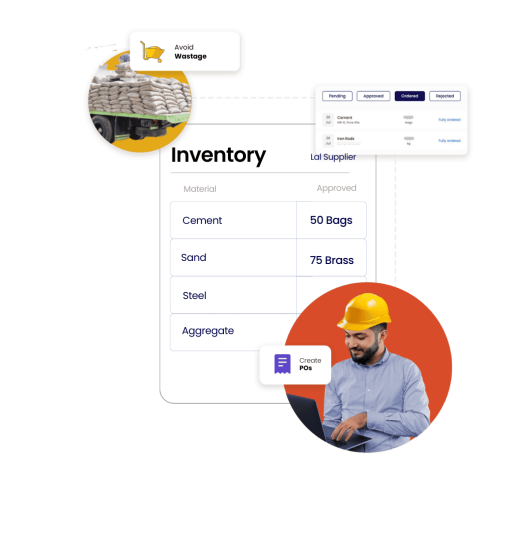

No Integration with Material Inventory

Most teams don't know which material was used where, making stock planning inaccurate and increasing procurement cost.

Production Cost Isn’t Linked to Project Budgets

Companies often discover overruns only after work is completed, affecting project profitability.

Why Choose Onsite Production Management Software

Standardize Material Mixes for Consistent Quality

Define and manage production recipes — like M10/M20 concrete, mortar ratios, plaster mixes, fabrication specs — and ensure every batch follows the approved composition.

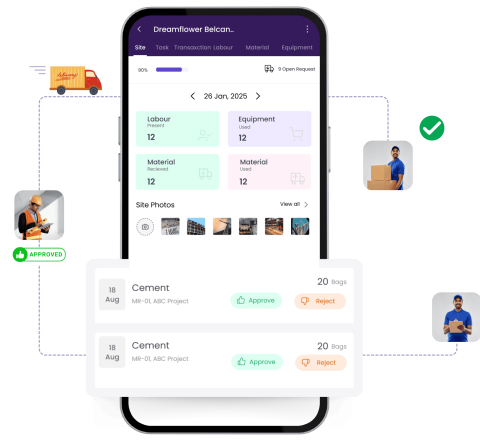

Track Input vs Output With Complete Transparency

Record raw material consumption and production output for each batch or shift. Onsite highlights deviations so you can control waste early.

Integrate Production With Inventory & Budgets

Every production run automatically updates material stock and contributes to project cost monitoring — ensuring full financial visibility.

What Our Customers Say About Us?

What makes Onsite Construction ERP Software Different from others

Built with Construction Experts,

For Construction Experts

Onsite is designed specifically for construction professionals—not just generic ERP users. From small builders to multi-site developers, we continuously evolve our features based on real-world input from the jobsite. Our tools streamline communication, automate site workflows, and adapt to the fast-paced nature.

Consistent Feature Enhancements

We release product updates regularly to reflect changing on-site demands. Whether it’s improving mobile usability, adding new integrations like Tally or Zoho, or refining features like GPS attendance and cost tracking, every release is made to remove friction and boost productivity.

Templates Built for Construction Teams

Preloaded with ready-to-use templates for project planning, material procurement, subcontractor billing, daily reports, and invoicing. These templates are fully customizable to match your internal processes—saving time and reducing rework.

Dashboards and Smart Reports

Track project progress, labor productivity, cost-to-completion, and profit margins—all from centralized, interactive dashboards. Real-time analytics help project managers and company owners make informed decisions without switching between ERP softwares & tools.

Smooth Migration from Excel & Other Tools

Moving from spreadsheets, WhatsApp, or disconnected tools? Our onboarding team makes it easy. We import your data, contacts, and site records to set you up on Onsite construction management software—fast and without any hassle.

FAQs on Onsite Construction Quality Management Software

What is Onsite’s Construction Production Management Software?

It is a digital system that helps construction companies manage material mixes, record batch production, track consumption, and monitor production efficiency in real time.

Who needs production management software in construction?

Contractors, developers, EPC firms, and industrial companies that handle concrete batching, plaster mixes, fabrication, or any form of in-house production benefit from it.

What problems does Onsite solve in production management?

It eliminates inconsistent material mixes, manual documentation errors, hidden material wastage, and the lack of linkage between production cost and project budgets.

Does Onsite support concrete and mortar production tracking?

You can define concrete grades (M10, M20, etc.), mortar ratios, plaster mixes, and log daily output with complete transparency.

How does Onsite track material consumption?

Onsite records the planned vs actual consumption for each batch and automatically highlights deviations to detect wastage.

Is Onsite’s production module linked to inventory?

Every production run automatically updates material stock in the inventory module to maintain accurate real-time stock levels.

Can Onsite track production cost impact on project budgets?

Absolutely. Production data directly connects with project budgeting, helping companies understand cost overruns early.

Does Onsite support batch-wise and daily production logs?

Yes. Teams can record production on a per-batch, per-shift, or per-day basis with complete traceability.

How does Onsite help improve production quality?

Standardized material mixes, accurate input-output tracking, and digital oversight ensure consistent quality and reduce rework.