Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Different Types Of Cement Every Contractor Should Know

Hydraulic V/S Non-Hydraulic Cement

Cement is a mixture of different constituents and acts as the main constituent in concrete. Cements are categorized into two categories:

Hydraulic Cement

Hydraulic cement is cement that hardens in the presence of water. This process is known as Hydration. One of the main advantages of hydraulic cement is that it can also be used in underwater construction projects.

Non-Hydraulic Cement

Non Hydraulic cement is cement that doesn’t harden in the presence of water. Hydraulic cement hardens in the presence of atmospheric carbon dioxide. This process is known as “carbonation.”

The main advantage of non-hydraulic cement is that it is immune to attack by chemicals after setting, which provides stability to the structure.

Types of Cement

1- Ordinary Portland Cement

OPC is the most common type of cement which is used in the construction industry. The main advantage of OPC is that it provides great resistance against cracking and dry shrinkage

Types of OPC

- 33 Grade.

- 43 Grade.

- 53 Grade.

Note- The grade represents the strength of the cement at 28 days

2- Rapid Hardening Cement

Rapid hardening cement is used in road work and bridge construction, where the time factor is very important. The cement is produced by mixing two compounds which are calcareous and argillaceous.

The chemical composition of rapid-hardening cement is almost the same as that of ordinary portland cement. The only difference is that rapid-hardening cement is more finely grounded.

3- Quick Setting Cement

Quick-setting cement is used for conditions where extreme pumping is required or in submersible land areas. These types of cement are mostly used in typical grouting operations. The advantage of using quick-setting cement is that it sets and gets dry very fast. This is done by reducing the quantity of “Gypsum” at the time of clinker grinding.

4- Low Heat Cement

Low-heat cement is used in construction projects such as the construction of gravity dams. Low-heat cement, because of its low-heat nature due to Hydration, prevents the cracking of concrete due to heat. This particular cement also has increased power against sulfates.

5- Sulfates Resisting Cement

Sulfate-resisting cement is used in constructions that are exposed to severe sulfate action by water and soil. Sulfate-resisting cement is used to reduce the risk of sulfate attack on any structure. This cement is particularly used in the construction of “foundations,” where the content of sulfate is much higher in the soil.

6- Blast Furnace Slag Cement

Blast furnace slag cement is mostly used for structures that are meant for water retaining; examples of such structures are water retaining walls, ports, tunnels, dams, etc. Blast furnace slag cement is made by mixing ordinary portland cement with finely granulated blast furnace slag.

7- High Alumina Cement

High alumina cement is widely used in marine and sewer infrastructure construction projects. It is also used in construction projects where the concrete is subjected to high temperatures. The reason for using this cement in these types of construction projects is their strength and rapid hardening properties.

Also Read: Comparing Cement Prices In India: A Guide To Finding The Most Cost-Effective Option

8- White Cement

White cement is mostly used for joining tiles and other interior works in the building’s surface areas. These are used for repairing marble tiles, floors, and roofs. White cement is obtained by lowering the iron oxide content from ordinary portland cement.

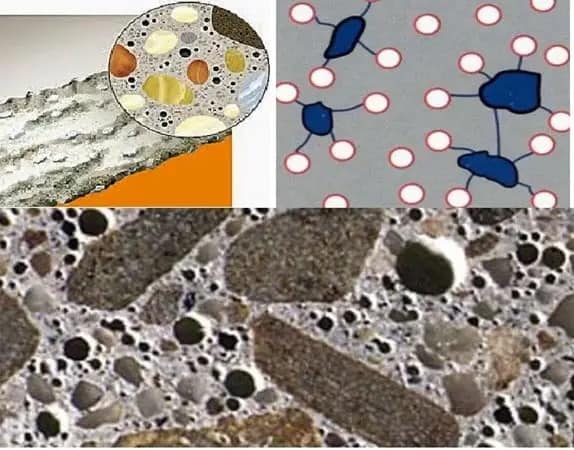

9- Air Entraining Cement

Air-entraining cement is manufactured by adding an air-entraining agent in power or in liquid form with an OPC cement clinker. There are other external materials added, are animal and vegetable fats, oil, and another acid with a certain wetting agent like aluminum powder, hydrogen peroxide, etc. By introducing an air-entraining agent, frost-resisting characteristics of hardened concrete are increased. The workability, segregation, and bleeding properties of concrete are improved by using this cement.

10- Expansive Cement

Expansive cement is used to overcome shrinkage loss and is an essential part of sealing joints. The advantage of expansive cement is that it does not shrink during and after the time of hardening, but it expands slightly with time in the construction process. Expansive cement consists of portland cement with added calcium sulfate and sometimes tricalcium aluminate.

Also Read: The Top 5 PPC Cements Used by Top Construction Companies in India

Conclusion

These are the types of cement that are used in almost every type of construction work. A contractor should always be very careful while choosing a type of cement for their construction projects

Popular FAQs on Types of Cement

Q1. What are the two main categories of cement?

Answer –Cement is categorized into two main categories: Hydraulic Cement and Non-Hydraulic Cement.

Q2. What is Hydraulic Cement, and how does it harden?

Answer –Hydraulic cement hardens in the presence of water through a process known as hydration. It can even be used in underwater construction projects.

Q3. What is Non-Hydraulic Cement, and how does it differ from Hydraulic Cement?

Answer –Non-hydraulic cement does not harden in the presence of water; instead, it hardens when exposed to atmospheric carbon dioxide through carbonation. It remains immune to chemical attacks after setting.

Q4. What are the different grades of Ordinary Portland Cement (OPC)?

Answer –OPC comes in different grades, including 33 Grade, 43 Grade, and 53 Grade, which represent the cement’s strength at 28 days.

Q5. Where is Rapid Hardening Cement commonly used?

Answer –Rapid Hardening Cement is used in road work and bridge construction, where time is crucial. It is produced by finely grinding a similar composition to Ordinary Portland Cement.

Q6. When is Quick Setting Cement used, and what advantage does it offer?

Answer –Quick Setting Cement is used in conditions requiring fast setting, such as extreme pumping or submersible land areas. It sets and dries quickly, achieved by reducing the quantity of gypsum during clinker grinding.

7. In which construction projects is Low Heat Cement preferred?

Answer– Low Heat Cement is used in projects like gravity dams to prevent concrete cracking due to heat generated during hydration. It also has increased resistance against sulfates.

Q8. What is Sulfate Resisting Cement used for?

Answer- Sulfate Resisting Cement is used in constructions exposed to severe sulfate action by water and soil to reduce the risk of sulfate attack. It is particularly suitable for foundations in high-sulfate soil.

Q9. Where is Blast Furnace Slag Cement commonly applied?

Answer – Blast Furnace Slag Cement is primarily used in water-retaining structures like walls, ports, tunnels, and dams. It’s made by mixing Ordinary Portland Cement with finely granulated blast furnace slag.

Q10. What are the typical applications of High Alumina Cement?

Answer –High Alumina Cement is widely used in marine and sewer infrastructure projects and in constructions exposed to high temperatures due to its strength and rapid hardening properties.

Q11. When is White Cement used in construction?

Answer –White Cement is primarily used for joining tiles and interior work in building surfaces, including repairing marble tiles, floors, and roofs, achieved by reducing iron oxide content.

Q12. How does Air Entraining Cement improve concrete properties?

Answer –Air Entraining Cement enhances frost resistance, workability, and reduces segregation and bleeding properties of concrete. It achieves this by introducing an air-entraining agent during manufacturing.

Q13. What is the purpose of Expansive Cement in construction?

Answer –Expansive Cement is used to overcome shrinkage loss and seal joints. It expands slightly with time during the construction process, preventing shrinkage.

Q14. Which type of cement should a contractor choose for their construction projects?

Answer –The choice of cement depends on the specific requirements of the project. Contractors should consider factors like the construction type, environmental conditions, and desired properties when selecting a cement type.

People also search: types of cement, different types of cement, non hydraulic cement, difference between hydraulic and non hydraulic cement, hydraulic and non hydraulic cement, hydraulic cement and non hydraulic cement, types of cement and their uses, what are the different types of cement, types of cement images, rapid hardening cement uses & difference between hydraulic cement and non hydraulic cement, non-hydraulic cement, different cement types,