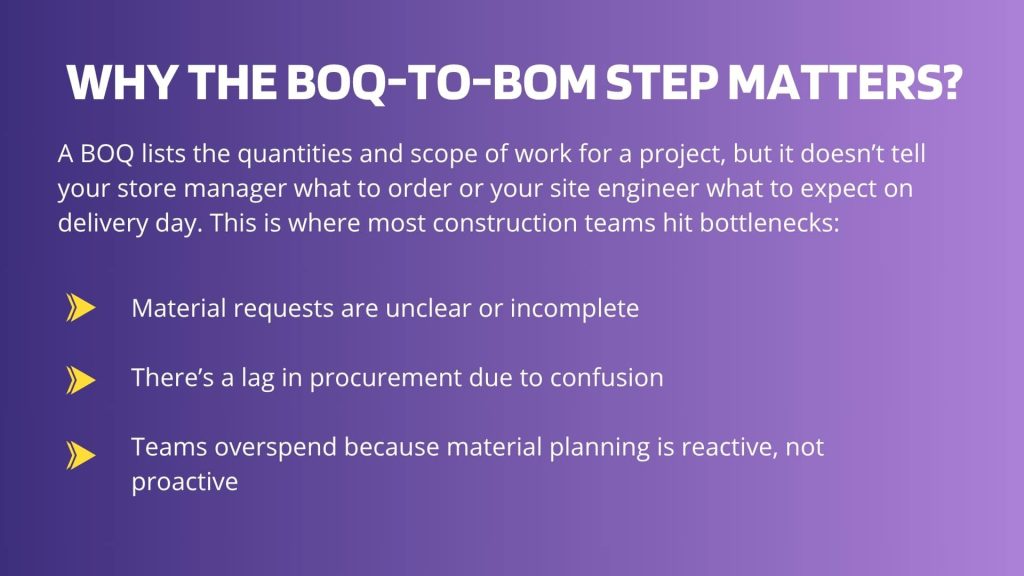

Project planning is a complicated thing when it comes to construction businesses. Managing materials, timelines, and costs often feels like chaos. One of the areas full of confusion and chaos is turning your Bill of Quantities (BOQ) into an accurate Bill of Materials (BoM). It doesn’t have to be as hard as it is. Let Onsite help you with converting your BOQs into Bill Materials. Wanna know how? Let’s get to know.

Onsite: Making It Easy to Convert BOQs into Bill of Materials

1. Accurate Material Planning, Every Time

With Onsite you make fewer mistakes and do less back-and-forth between teams. You get a clear list of what materials are needed, how much, what size, and which specification. You can even categorize them by trade (civil, plumbing, electrical), material type, or vendor. This structured BOM ensures nothing is missed, making your procurement process faster, more accurate, and easier to manage.

2. Stay on Budget with Better Cost Control

Cost control is one of the major factors in any construction project. Onsite helps you with over ordering, accurate data, and better decision making. With Onsite, you can know what material is available at what site and how much of it is used every day. In this way you can avoid over ordering and make better decisions on purchasing material.

3. No More Delays

Nothing slows down a project more than material shortages or delays. Onsite gives you a clear view of how much material is available at site and if more is needed. Site supervisors can even make a request if they need material according to which a BOQ can be made, and you can easily convert BOQ in Bill of Materials.

4. Align Store, Site, and Accounts

A confusion between store, site, and accounts team can create many problems like delays and cost overruns. Onsite comes here to help you by centralizing your material plan, directly linked to your BOQ.

A site supervisor when see that more material will be needed, he informs the backhand team directly from the app. So, Onsite knows what’s needed and when, ensuring better stock management. The stock management team can approve the request. The accounts team can easily see, and check material used and how much it costs. This helps in making billing and payments more accurate. This helps in avoiding duplicate orders and any kind of mistake. It also helps in creating accountability and a smoother process of converting BOQs into Bill of Materials.

Conclusion

Onsite is not just another software out there, it is made for the construction field and it helps in everything including converting BOQs into Bill of Materials. If you’re tired of dealing with the headaches of manual BOQ-to-BoM conversions, it’s time to give Onsite a try. Book a demo today and see for yourself how our platform can make project planning easier, faster, and more efficient.

FAQs

1. What’s the difference between a BOQ and a Bill of Materials (BoM)?

A BOQ (Bill of Quantities) gives an overall view of the scope of work and estimated quantities for a construction project. In contrast, a BoM (Bill of Materials) gets into the nitty-gritty details, specifying exactly what materials are needed — like size, type, quantity, and other specs — to actually complete the job on-site.

2. Why is converting BOQs into BoMs so important?

Without converting your BOQ into a BoM, material planning can be vague and full of room for error. A BoM provides clarity, making sure everyone — from the site crew to procurement — knows exactly what’s needed. This reduces mistakes, delays, and the dreaded cost overruns.

3. How does Onsite help convert BOQs into Bills of Materials?

Onsite takes care of the heavy lifting by automatically converting your BOQ into a BoM. It breaks down each work item into clear material requirements, groups them by trade or vendor, and consolidates everything into one organized plan that’s easily accessible by all teams.

4. Can Onsite help prevent over-ordering of materials?

Absolutely. Onsite tracks material usage in real-time across all sites, giving you clear visibility of what’s in stock and what’s being used. This helps you avoid overstocking or running into last-minute shortages, ensuring you only order what’s truly needed.

5. How does Onsite improve coordination between store, site, and accounts teams?

Onsite brings everyone onto the same page with a shared material plan. Site supervisors can request materials, the store team tracks stock, and the accounts team can view costs — all within the same platform. This reduces miscommunication and fosters real-time accountability.