Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Streamlining Material Management Processes in Construction

Material management in construction is one of the major tasks that is necessary to be efficient. Keeping its track and managing its pricing is a must otherwise your project’s budget and planning will be shaken. There are often times when the materials cost too much, sometimes it’s overstocked, sometimes there’s shortage, and just like this there are many factors that affect the management of material and material management process. Let’s get to know about unique challenges that are faced during material management Processes.

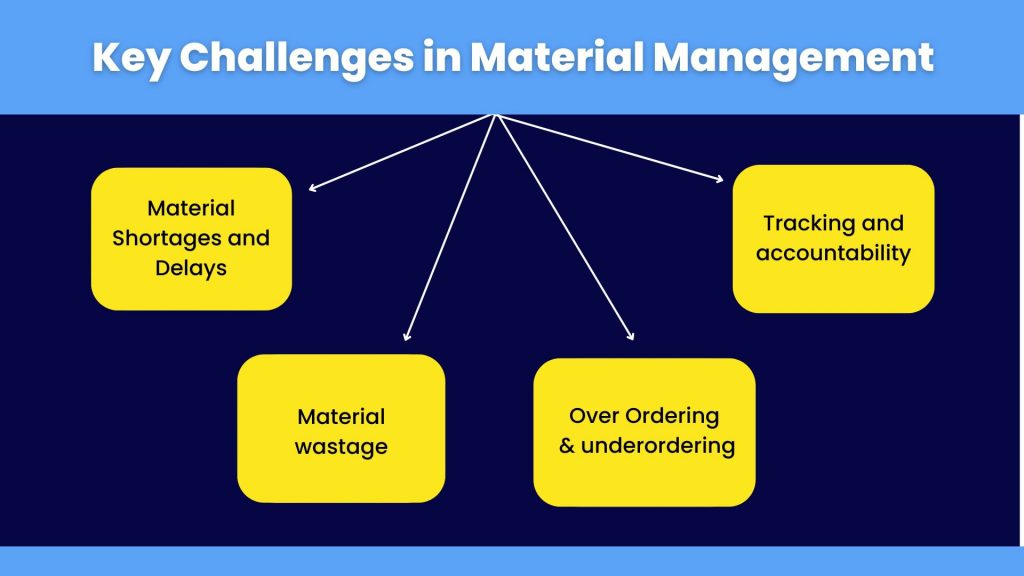

Key Challenges in Material Management

During material management contractors often face many challenges. Following are some of the key challenges in Material Management:

1. Material Shortages and Delays

Often there is a shortage of material, and it happens because of the poor material usage planning. There are times when because of poor coordination with suppliers, delays in delivery of material can take place.

2. Over Ordering & underordering

Errors in estimating the required quantity of materials may result in overstocking, which brings about storage challenges and additional costs, or underordering, which can cause project delays.

3. Tracking and accountability

Managing and keeping track of materials on large construction sites can be difficult, leading to misplaced items or unrecorded usage. This is the reason why proper way of tracking material becomes necessary.

4. Material wastage

Inefficient handling, incorrect ordering, or improper storage of materials often leads to wastage, increasing project costs and environmental impact.

Best Practices for Streamlining Material Management

1. Accurate Forecasting and Planning

In material management, it is necessary to have proper planning and forecasting otherwise there could be many mishappenings like unrecorded material, over usage, misplaced material, material wastage, etc. Accurate forecasting and planning can be done with the help of construction project management tools like Onsite. Onsite helps contractors or owners to get real-time updates of material usage and their location. So, that it can be monitored how much material is being used and where it is being used. By accurately forecasting, you can also estimate material for future usage.

2. Just-in-Time (JIT) Delivery

Just-in-Time (JIT) Delivery helps in avoiding problems like excess storage cost and project delays. Timely delivery of material helps in maintaining the project’s productivity and efficiency. It also eliminates the risk of overstock of material. With the help of JIT Delivery, the project remains productive and efficient.

3. Collaboration & Communication

Collaboration & Communication with the suppliers is one of the most important factors that is needed to be considered while handling a construction project. Poor coordination and communication with suppliers can lead to project delays, material shortage, and price fluctuation. Poor conversation and collaboration can lead to bad material management process.

4. Centralized Inventory Management

A proper and centralized way of tracking material can avoid problems like overstocking and understocking. You can keep track of every single material and get to know how much of it is used and how much of it remains. In this way you can properly utilize the material and get to know if there’s any over usage of it. You can also track delivery of material like when it reached at the site. You can track your material with the help of construction management software like Onsite. It helps you get real-time updates on material.

5. Standardization of Materials

Standardization of material helps in better procurement while avoiding any complexity in it. It also helps in simplifying inventory management. Bulk purchase of material can lead to cost saving and faster delivery times. Suppliers are often likely to give huge discounts on bulk purchase. With the help of Onsite, you can generate POs and have a smooth material procurement process.

Conclusion

If you are someone who struggles with material management process, then above information is for you. Some basic practices to streamline your material procurement are accurate forecasting & planning, Just-in-Time (JIT) Delivery, Collaboration & Communication, Centralized Inventory Management, and Standardization of Materials. So, if you are involved in the construction industry then you should follow the above practices. You can use construction management software like Onsite to have better results in your material management.

Also Read: Inventory Management in Construction: Unique Challenges

FAQs

1. Why is material management crucial in construction?

Material management is essential in construction to control costs, avoid delays, and ensure that materials are available when needed. Efficient material management keeps projects on track, prevents budget overruns, and helps maintain quality standards.

2. What are the key challenges faced in material management?

Some key challenges include:

- Material shortages and delays due to poor planning or supplier issues.

- Overordering or underordering materials, leading to excess storage costs or project delays.

- Tracking and accountability for materials, which can lead to misplaced or unrecorded usage.

- Material wastage due to inefficient handling or storage.

3. How does accurate forecasting and planning benefit material management?

Accurate forecasting and planning prevent issues like overordering, underordering, and material wastage. It also allows contractors to better anticipate future material needs. Tools like Onsite assist with real-time tracking and updates, ensuring efficient material use.

4. What is Just-in-Time (JIT) Delivery, and how does it help in material management?

Just-in-Time (JIT) Delivery is a strategy that ensures materials arrive exactly when needed, reducing storage costs and minimizing the risk of overstock. It improves project efficiency by eliminating material-related delays and optimizing inventory flow.