Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Free Steel Weight Calculator For Column

Welcome to our Steel Weight Calculator for Columns – the ultimate tool for accurately gauging the load-bearing capacity of steel columns. Whether you’re an engineer, architect, or part of the construction team, knowing the weight a steel column can support is crucial for a successful project. Our calculator delivers quick and precise results, empowering you to make well-informed decisions about column specifications. Forget about manual calculations; say hello to straightforward precision. Simplify your structural design process and ensure project safety with our Steel Weight Calculator for Columns. Let’s construct more robust, smarter structures together.

How to Use Brick Calculator for Wall?

Let’s understand with the help of an example, how to use the above Steel Calculator for Column.

Part 1: Calculation for Main Bars

Assumptions for Example

- There are 2 types of bars: Bar1 & Bar2

- 4 Nos of Bar1 and 4 Nos of Bar2 are required for the column

- Bar1 Diameter = 20 mm

- Bar2 Diameter = 16 mm

- Height of Slab = Distance between Floor & Slab = 5000 mm

- Slab Thickness = 150 mm

- We are using Steel grade of fe500

Calculation Procedure

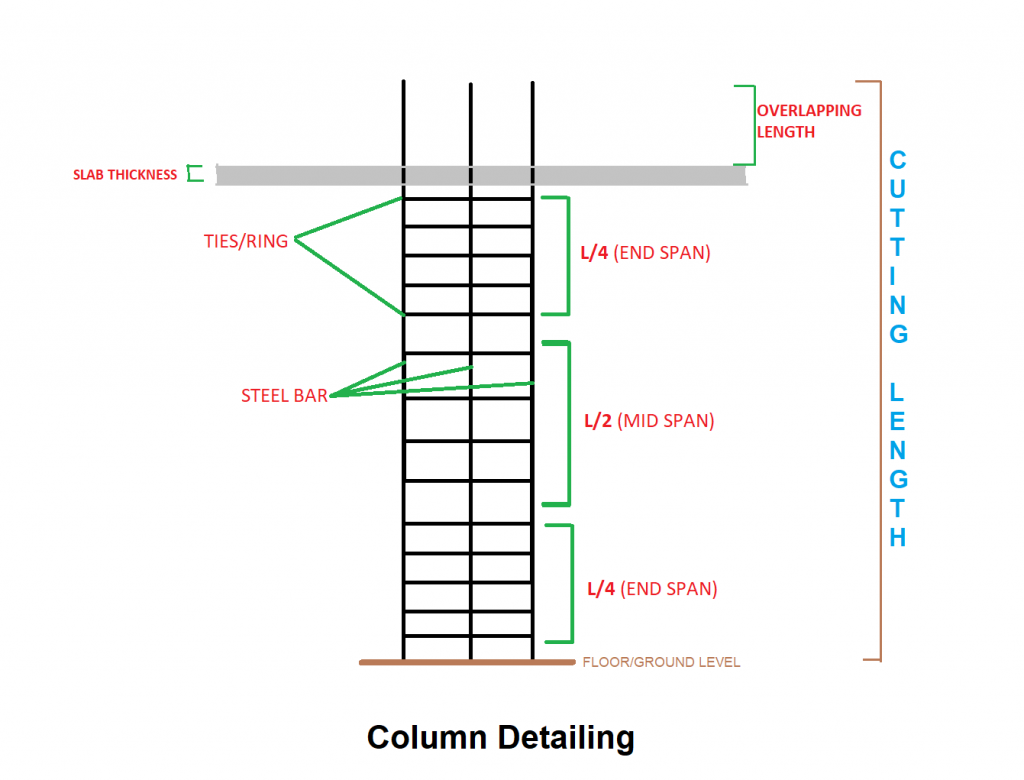

Step 1: Check the Height of Floor on which column to be casted

Length of the Main bar runs parallel with the height of the floor.

Step 2: Note the Overlap length and Slab thickness (150 mm)

Length of the main bar is an addition of height of the column, height of the top slab and overlap length which is added to the top end of the column for the next floor purpose.

Length of Bar = Height of the Slab + Thickness of the slab + Overlap Length.

Step 3 Note Diameter of Bars.

Step 4: Calculate the total length of the main bar

Cutting Length of Bar1 = (5000 + 150 + (50×20)) = 6150 mm

Total Length of Bar1 = 6150 x 4 = 24600 mm

Cutting Length of Bar2 = (5000 + 150 + (50 x 16)) = 5950 mm

Total Length of Bar2 = 5950 x 4 = 23800 mm.

Step 5: Find the total weight of main bars

Weight of the bar as per their length and diameter by following Formula: –

Unit weight formula for kg per metre =(D^2/163) × L kg/m

Unit weight for feet per metre = (D^2 / 533) × L kg/ft

L is the required length of Steel bar of Diameter D

Result

Weight of Bar1 (4 Nos) = (202/163) x 24.6 = 60.37 KG

Weight of Bar2 (4 Nos) = (162/163) x 23.8 = 37.38 KG

Part 2: Calculation for Ties & Stirrups

Assumptions For Example

Length of the column = 450 mm

Width of the column = 300 mm

Diameter of Ties= 8mm

Spacing between Ties at ends = 150 mm

Spacing between Ties at mid = 200 mm

Hook Length = 10d or 75 mm

90° Bend = 2d

135° Bend = 3d

Concrete Cover = 25 mm

Calculation Procedure

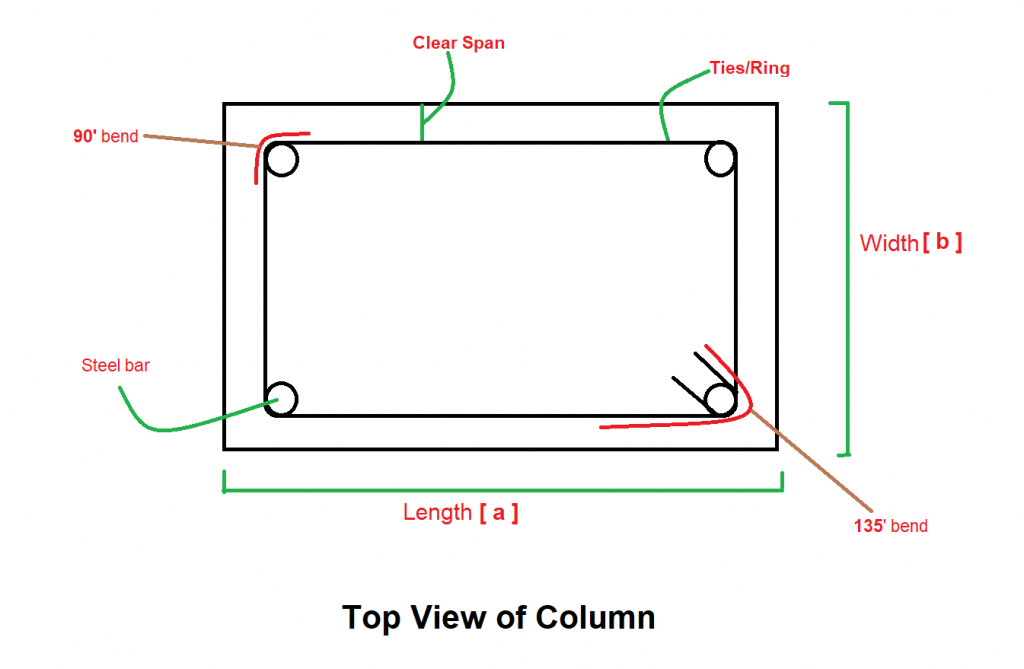

Step 1: Deduce the Concrete Cover from all sides of tie and find out the length of ties

As shown, [ 2((a-concrete cover) + (b-concrete cover)) ].

Step 2: Calculate the length (cutting length) of ties including hook and deducting bends (90° & 135°)

Cutting Length of ties = 2((a-concrete cover) + (b-concrete cover)) + 2 numbers of hooks – 3 numbers of 90° bends-2 number of 135° bends

= 2((450-25) + (300-25)) + 2x10x8 -3x2x8 – 2x3x8 = 1464 mm

Step 3: Then Find out the total no. of ties with the help of Center to the center distance at mid and end span

No. of Ties at mid Span = ((L/2)/ mid-span spacing) + 1

No. of Ties at End Span = 2*[((L/4)/ mid-span spacing) + 1]

No. of Ties = No. of ties at end span + No. of ties at mid span

= 2[((5000/4)/150) +1] + [((5000/2)/200) +1]

=18+14 = 32

Step 4: Find the total length of ties

Total Length of Ties = 32×1464 = 46848 mm

Step 5: Note the Diameter of the ties.

Step 6: Calculate the total weight of ties

Weight of the tie bar as per their length and diameter by following Formula: –

Unit weight formula for kg per metre =(d^2/163) ×L kg/m

Unit weight for feet per metre = (d^2/533)×L kg/ft

L is the required length of Stirrup Steel bar of Diameter d

Result

Total Weight of bar for ties = (82/163) x 49.776 = 18.39 Kg

Final Result

Total Weight of Steel Required = 60.37+37.38+18.39 =116.14 Kg